Larson Building Systems Laboratory

The Larson Building Systems Laboratory is a unique facility in the HVAC industry that permits the study of entire HVAC systems in a controlled dynamic environment, providing repeatable test conditions that have been previously unavailable.

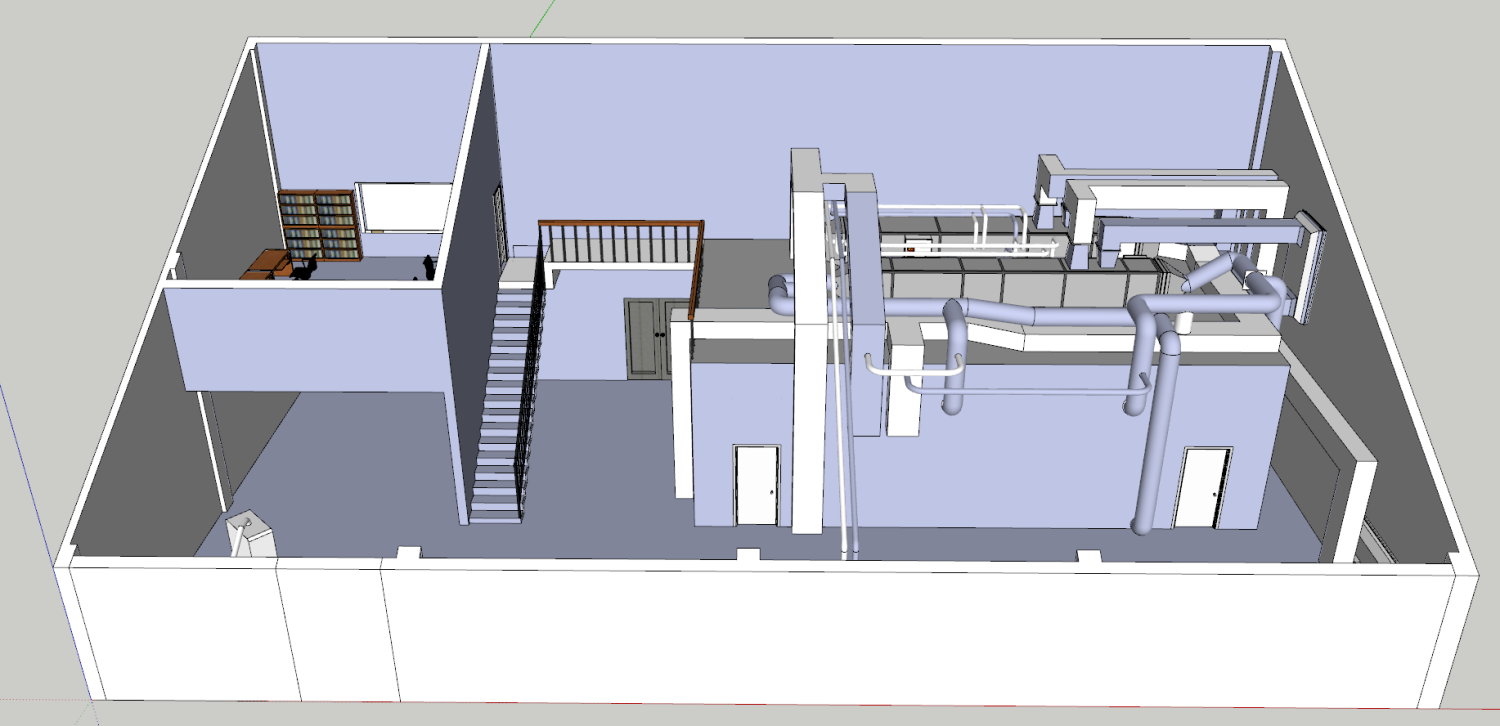

It is used for education and research and is designed for dynamic testing of complete and full-scale commercial HVAC and building systems. The facility consists of a full-size commercial HVAC system, four representative commercial building zones, a system for producing repeatable and controllable loads, and sophisticated data acquisition and control systems.

Activities at the laboratory include evaluation and testing of control algorithms and hardware for HVAC components and systems, interactions between multiple control functions of HVAC systems, the dynamic interactions between building thermal response and HVAC system controls, ventilation control for indoor air quality, and HVAC system diagnostics.

The laboratory offers maximum flexibility to encourage a variety of research and testing procedures. In particular, both the HVAC and control systems in the laboratory are reconfigurable in that components, subsystems or entire systems can be readily installed, tested, and modified.

The performance of air handling units, displacement ventilation units, chilled beams, and variable refrigerant flow units can all be tested in the lab. In addition, coils, air mixers, dampers, filters, and variable frequency drives can be evaluated. Moreover, the laboratory offers the possibility to test standalone HVAC and refrigeration systems such water heaters, boilers, thermal energy storage tanks, and chillers.

Overview of the Larson HVAC laboratory.

The facility offers an ideal environment to test a wide range of operational and control strategies for HVAC systems and subsystems, with laboratory sensors and control points that can be accessed locally and remotely. We are able to test demand-ventilation controls, optimal chiller and thermal energy storage controls, outdoor air intake controls, and optimal operation of evaporative systems. In addition, fault diagnostic algorithms have been tested in the laboratory, including for heating and cooling coils, chillers, and outdoor air intake.

The laboratory houses two full-size test chambers that can be used to model a large variety of indoor environment conditions such as offices, data centers, and hospital operating rooms.

The test chambers are well-insulated, sealed and equipped. Different heating, cooling and ventilation strategies and equipment are installed in the spaces including both air and water heating and cooling systems, displacement ventilation etc. We can accommodate up to 300 data channels with advanced data acquisition equipment and software. Data collected include temperature, humidity, pressure, flow rate, contaminant concentration, fan speed, and electric power consumption etc. The measurement accuracy meets or exceeds all relevant ASHRAE/ASTM standards. Advanced measurement techniques such as PIV, laser sheet visualization are also used for enhanced lab tests.

Through the Larson Laboratory, our students have unique learning opportunities, positioning them for successful careers in HVACR. Internship opportunities with the Larson Laboratory are also available for students to further enhance their HVAC knowledge and practical experience.

The Larson Building Systems Laboratory is situated in the CU Boulder Engineering Center, 1111 Engineering Drive, room ECCE 215.