Blog: Next generation metal 3D printing

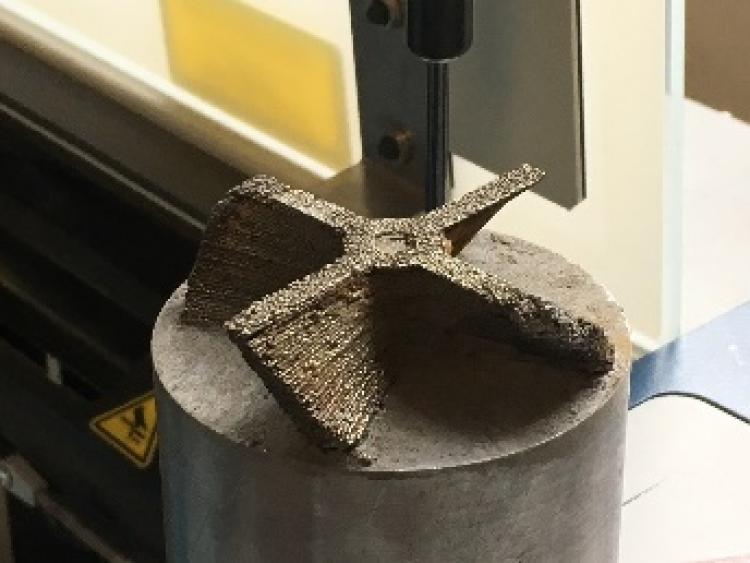

Propeller-shaped part printed by team for flaw detection using vibrational analysis.

In the last several years, 3D printing has taken off as a convenient method to creating plastic parts. It has become a relatively cheap and quick way to rapidly prototype a design concept with potentially complex geometries before taking it to large scale production. If there was a way to use 3D printing for the final production as well as for the prototyping it could have large scale impacts across many different industries from aerospace to biomedical.

Just recently this has become feasible as metal 3D printing has emerged as a form of additive manufacturing. There are problems however that are hindering metal 3D printing from becoming large scale production. Our senior design project, with client Elementum 3D, aims to develop a diagnostic technique that might revolutionize metal 3D printing.

Similar to plastic 3D printing, metal 3D printing is prone to having flaws in the print that affect the functionality or quality of the part. This is less important for plastic because it is less expensive and not usually used as the final product. For metal 3D printing, it can be very costly in both time and resources to realize that a print is not up to sufficient quality.

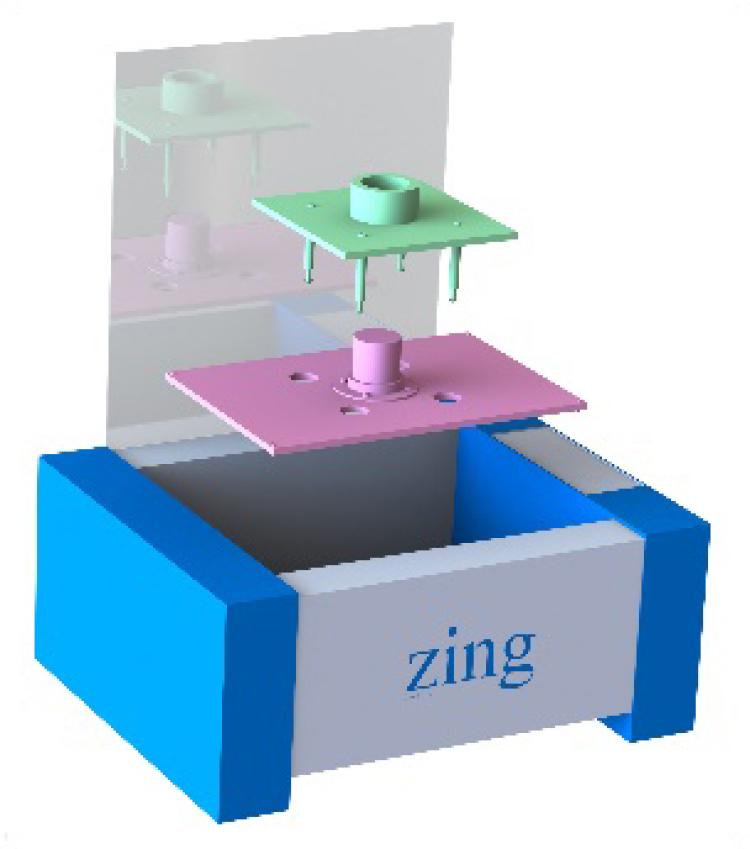

Rendering of the moving (pink) and fixed (green) subassemblies designed by the team to enable quality sintering with the Epilog Zing laser cutter.

The current system for searching for a flaw while metal 3D printing is to image the part and search the image to try to identify flaws on the surface of the part. This technique has significant limitations in flaw detection and scalability. With our client and director, we are exploring the feasibility of a real-time in-situ diagnostics of 3D printed metal parts.

The technique relies on measuring the vibrational pattern of the part while vibrating the part as it is being built. If there is a flaw, either internal or external, the vibrational pattern should change. This concept could change the course of 3D printing metal because flaws in a part would be known by the time the part was finished printing.

To start, we needed an in-house metal 3D printer that we could use for testing. We modified an Epilog Zing 16 laser cutter for this purpose. The Zing is a good candidate for the conversion into a 3D printer because it has a strong CO2 laser that can sinter metal powder together, however the Zing was not designed to build three-dimensional parts.

Our redesign incorporated a moving subassembly and a stationary one, in order to allow the print to always be in the optimal focal point of the laser. We had to design methods for vibrating the part, as well as measuring the vibrations while minimizing the observer effect.

For this, we used a Laser Doppler Vibrometer (LDV) on loan from Polytech for. The LDV allowed for the measurement of the resonance frequency of the part during any stage of the print because it did not need to be attached to the printing object.

Senior Design Team:

Nick Seitz

Chris Worsdale

Eric Fisher

Anouk Uragoda

Kevin Oh

Grant McNutt

Director:

Dr. Gerard Carroll

Client:

Dr. Jacob Nuechterlein - Elementum 3D

We learned that the testing would not be as easy as quickly printing a piece of metal and measuring the vibrations. The Zing was being pushed to its limits of performance because of how demanding the printing was. We were using the machine for functions that it was not designed for, so we had to diagnose, troubleshoot, modify, repair the Zing, the sensors, and data acquisition to allow for proper measurements.

While this system became more complicated than initially intended, the idea and the technology has the potential to change large sectors of the manufacturing industry. Many engineering industries would be affected by the ability to create a 3D printed metal part and knowing the presence and size of flaws. This technology would open the door for the use of metal 3D printing as a major player in advanced manufacturing.

Special Thanks:

Polytech – LDV loan

Epilog – Support and advice for Zing

Illustration of the motion of the stage as a part is printed. The metal powder for the part (shown in pink) is contained within the retaining ring (shown in green).