Research briefs

New centers, spaces and projects to watch

NEW INITIATIVE

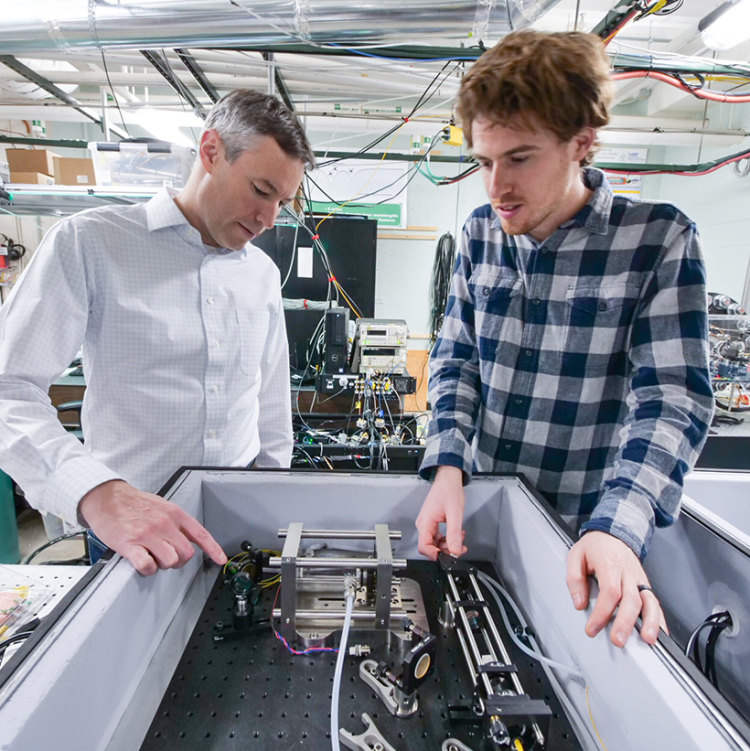

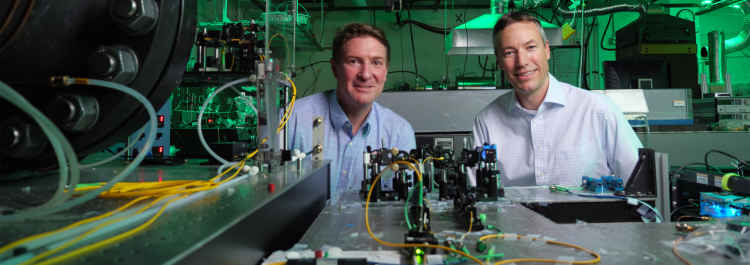

Quantum Engineering Initiative lead Greg Rieker, right, with Scott Diddams in the lab.

A quantum leap forward

The college has launched a Quantum Engineering Initiative to expand internal efforts in the field while strengthening connections to local and regional partners.

The initiative marks a significant and strategic investment into translational quantum engineering research — especially in quantum sensing, which has been a strength in the college for years. It specifically includes educational components, faculty hiring efforts and dedicated lab space for collaboration with partners both on and off CU Boulder’s campus.

The initiative is a new arm of the existing campuswide CUbit Quantum Initiative, which supports the university and state of Colorado’s prominence in quantum information science and technology.

The college took another bold step forward in 2021 by hiring Professor Scott Diddams and several other prominent quantum researchers into faculty roles. Diddams has worked at the National Institute of Standards and Technology for two decades and conducted prominent experimental research in the field of optical frequency combs and quantum metrology with application to atomic clocks and sensors.

Other recent hires include Assistant Professors András Gyenis and Josh Combes. All three are based in the Department of Electrical, Computer and Energy Engineering and are part of a multiyear faculty recruitment plan as part of the Quantum Engineering Initiative.