Part 4: Straining for Excellence

[Editor’s note: This is the final segment of a four-part series looking at the student-led Engineering Excellence Fund.]

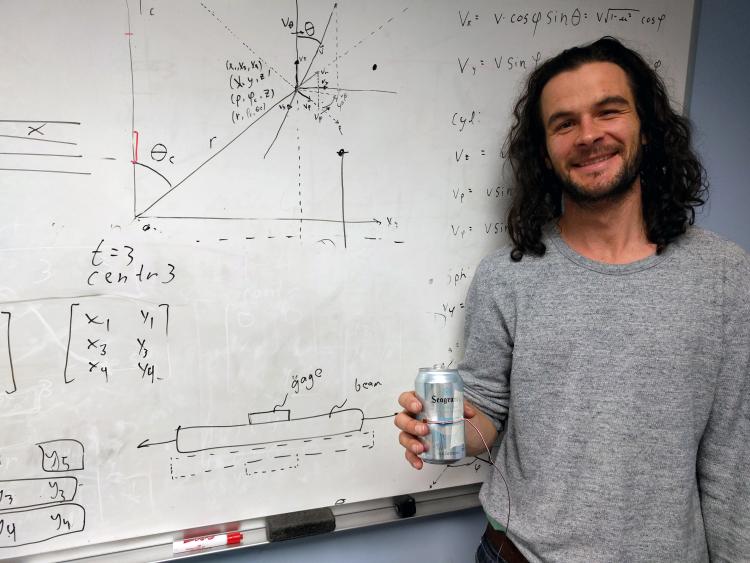

Using funding from the Engineering Excellence Fund, Regner is incorporating a new lab into MCEN 3047: Data Analysis and Experimental Techniques. The lab uses a strain gauge, a small sensor used to measure strain on an object, such as a beam.

“It’s mimicking and mirroring the movement of whatever it’s attached to,” Regner explained.

In Regner’s lab, no beams are in use, rather soda cans are tested to determine their internal pressure. After super-gluing the strain gauge to the can, measurements from the strain gauge are taken before and after opening the can.

“When the soda can decompresses, the electrical resistance of the strain gauge changes,” Regner said. “But because that change is so small, a special circuit is required to increase sensitivity to this change in resistance.” This accounts for the three wires that connect to the strain gauge, providing a more documentable value to the experiment.

“It’s one of the more fundamental sensors in science and engineering. Here it is used in a simple way, but they can also be used to solve more complex problems,” Regner said.

The idea for the lab came after Regner taught the class for two semesters and felt something was missing.

“This is a class related to everyday life as an engineer, but it’s only as useful as its labs,” he said. “I thought the labs could be improved, and this is a step in the right direction.”

“This lab incorporates every one of those processes.” Regner said. “It allows for students to use theory they learned in other classes and apply it to a real life situation.” He paused before adding, “And it’s fun.”

Regner did a similar lab in his undergraduate career at Virginia Tech, and he still has fond memories he wants to share with his students.

“I want students to think back and say ‘I remember that soda can lab; that was awesome!’ just like I do,” he said.

But without funding from the student fees that pay into the Engineering Excellence Fund, none of this would be possible.

“With the funding from EEF, I’m able to run this lab for six semesters,” Regner said. “With 100 students per semester, that’s a pretty high student impact."