Volumetric Additive Manufacturing

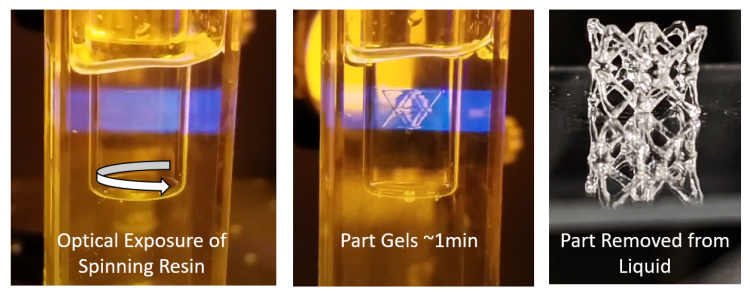

The new field of Volumetric Additive Manufacturing (VAM) optically prints 3D structures into a sealed, fixed volume of liquid photosensitive resin via tomographically computed projections. Since resin need not move during printing, writing into very high viscosity or even solid materials becomes possible, enabling final print material properties previously unattainable in additive manufacturing. Prints typically take tens of seconds to a few minutes - about 100x faster than stereolithography - with resolution in the tens of microns possible. The ability to rapidly print into a wide range of resins in a sealed package has exciting applications in microfluidics, bioprinting, refractive index patterning, and any other application requiring speed and high resolution over a wide range of material properties.

The team

- Charles Rackson

- Darren Liu

- Gabe Seymour

- Johnny Hergert

Learn More

[1] Charles M. Rackson, Joseph T. Toombs, Martin P. De Beer, Caitlyn C. Cook, Maxim Shusteff, Hayden K. Taylor, Robert R. McLeod, "Latent Image Volumetric Additive Manufacturing", Optics Letters. 47, 1279-1282 (2022).

[2] Charles M. Rackson, Kyle M. Champley, Joseph T. Toombs, Erika J. Fong, Vishal Bansal, Hayden K. Taylor, Maxim Shusteff, Robert R. McLeod, "Object-space optimization of tomographic reconstructions for additive manufacturing", Additive Manufacturing 48, 102367 (2021).

[3] Cook, C. C., Fong, E. J., Schwartz, J. J., Porcincula, D. H., Kaczmarek, A. C., Oakdale, J. S., Moran, B. D., Champley, K. M., Rackson, C. M., Muralidharan, A., McLeod, R. R., Shusteff, M., “Highly Tunable Thiol‐Ene Photoresins for Volumetric Additive Manufacturing.” Adv. Mater. 2020, 2003376, 2020. https://doi.org/10.1002/adma.202003376

This work has been generously funded by