Stem-cell Laden Implants for Cartilage Defect Repair

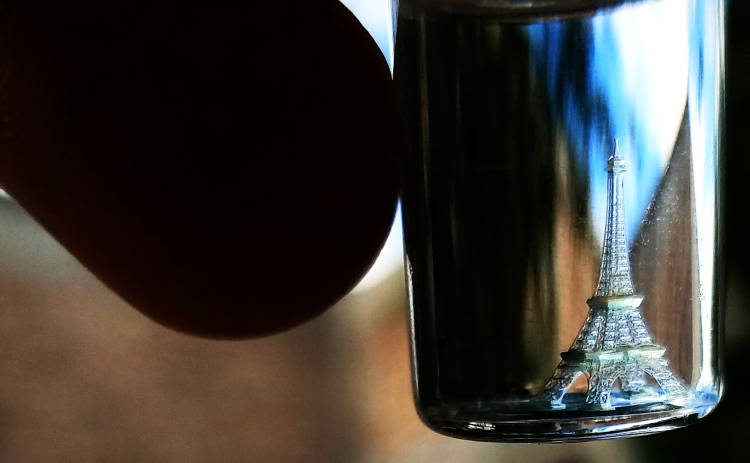

Three dimensional printing of polymers can be done through a moving orifice (e.g. fused deposition) or by photopolymerizing a liquid (e.g. stereolithography). In 2013, we developed a new form of stereolithographic printer using an image projector, a PDMS coated window and a moving platform, as shown below. This system can print significantly faster than the traditional scanning laser and recoating blade. We exploit this speed to print at very small (~micron) scale and very soft (KPa to MPa) polymers that are used in regenerative medicine. We are currently printing implants for defects of knee cartilage that may provide a cure to osteoarthritis.

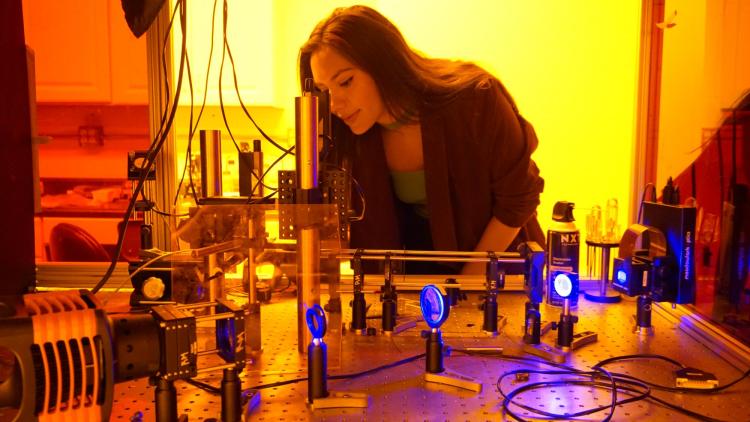

The team

- Camila Uzcategui

- Archish Muralidharan

- Johnny Hergert

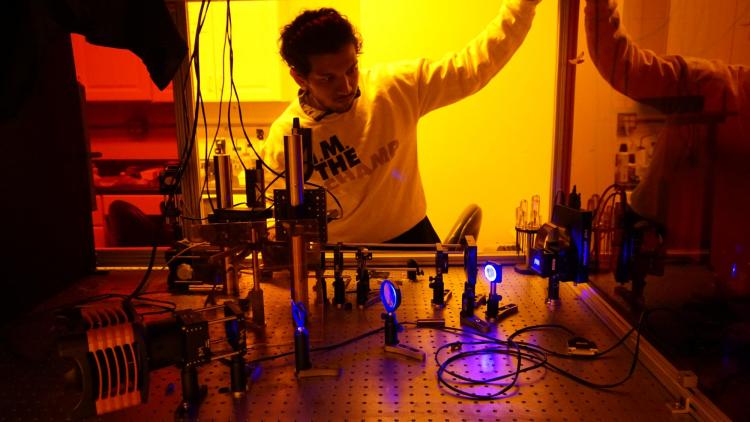

Showing off (sometimes we print things that are just for fun)

A printed Eiffel Tower suspended in ethanol in a vial. The dark blob on the left is a finger-tip.

X-ray tomography videos one and two of the printed Eiffel tower held by a finger

Learn more

- A. C. Uzcategui, A. Muralidharan, V. L. Ferguson, S. J. Bryant, and R. R. McLeod, “Understanding and Improving Mechanical Properties in 3D printed Parts Using a Dual-Cure Acrylate-Based Resin for Stereolithography,” Advanced Engineering Materials 2018, 1800876, 2018. Supplementary Information.

- Elizabeth A Aisenbrey, Andrew Tomaschke, Eric Kleinjan, Archish Muralidharan, Cecilia Pascual-Garrido, Robert R McLeod, Virginia L. Ferguson, Stephanie J Bryant, “A Stereolithography-based 3D printed Hybrid Scaffold for In Situ Cartilage Defect Repair,” Macromol. Biosci. 2017, 1700267, 2017

- Callie Fiedler, Characterization of the Properties of Photopatterned Hydrogels for Use in Regenerative Medicine, University of Colorado, 2017.

- C. I. Fiedler, E. A. Aisenbrey, J.A. Wahlquist, C. M. Heveran, V. L. Ferguson, S. J. Bryant, and R. R. McLeod, “Enhanced mechanical properties of photo-clickable thiol-ene PEG hydrogels through repeated photopolymerization of in-swollen macromere,” Soft Matter 12, 9095 – 9104, 2016

- A.C. Urness, E.D. Moore, K.K. Kamysiak, M.C Cole and R.R McLeod, Liquid deposition photolithography for submicrometer resolution three-dimensional index structuring with large throughput,” Light: Science & Applications 2 (Nature Publishing Group) , e56, 2013

- A. Linnenberger, M. I. Bodine, C. Fiedler, J. J. Roberts, S. C. Skaalure, S. J. Bryant M. Cole, R. R. McLeod,Three Dimensional Live Cell Lithography,” Optics Express 21, 10269-10277, 2013

This work has been generously funded by

Sample results

Layout of a stereolithographic printer. 405 nm light is patterned into a ~megapixel image by a DMD spatial light modulator and projected through a glass window into the exposure chamber. The interior of this window is coated with an oxygen permeable membrane that inhibits polymerization, preventing adhesion of the polymer to the window. As the platform moves, the image is changed, printing a 3D solid part from the liquid resin.

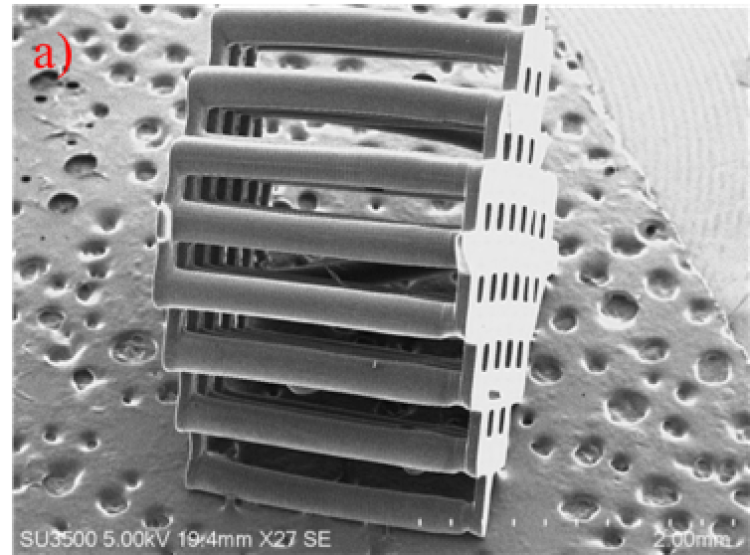

SEM of a hydrated PEG acrylate scaffold printed in our custom stereolithography system. The stiff scaffold is subsequently back filled with a soft hydrogel containing mesenchymal stem cells. This is implanted in a cartilage defect to regrow bone and cartilage, with the goal of preventing osteoarthritis.

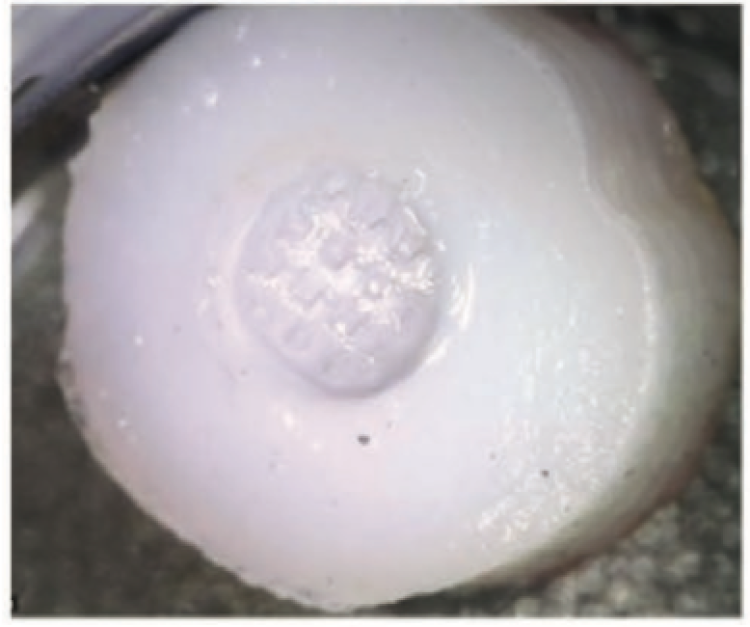

Focal chondral defect in an osteochondral plug explanted from the trochlear groove of porcine knees, then filled with the hybrid scaffold. The photograph was taken immediately after filling and prior to culture.