ATLAS makers print face shield parts to help protect medical personnel from the novel coronavirus

Joining the global grassroots response to shortfalls in personal protective equipment, members of the ATLAS community are 3D printing parts for face shields to help protect local medical personnel against the highly contagious novel coronavirus.

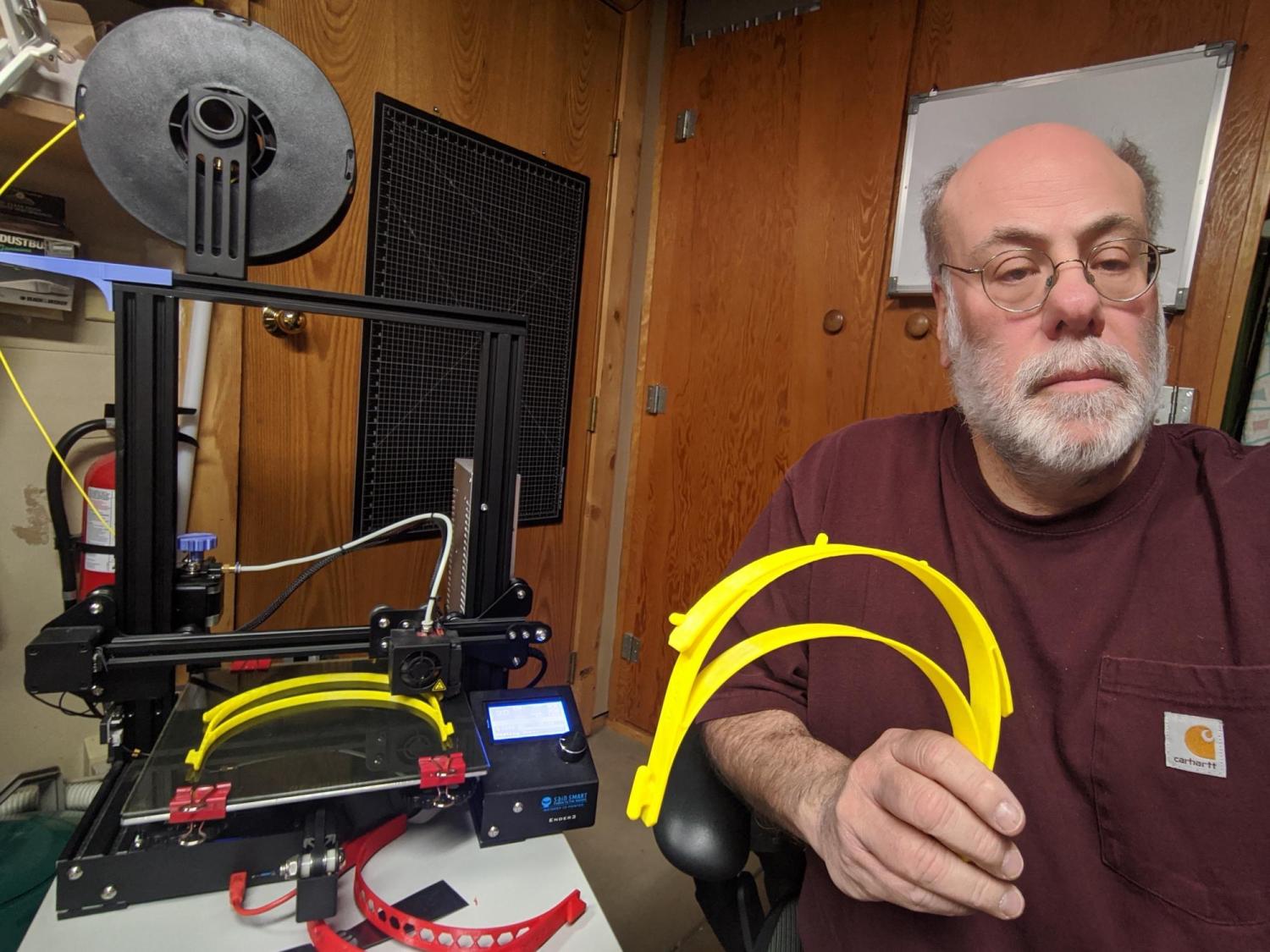

From basements, offices and closets the whirring sounds of 3D printers is heard day and night in the homes of at least six members of the ATLAS community: Pete Pascente, master’s student; Wayne Seltzer, technologist-in-residence; Zack Weaver, instructor and creative technologist for Boulder Library makerspace (BLDG 61); Sheiva Rezvani, instructor; Camilla Friedman-Gerlicz, instructor; and Aileen Pierce, senior instructor.

Together, they are part of the worldwide maker community that is sharing designs and making personal protective equipment to compensate for the global shortage that has left medical workers unable to adequately protect themselves and their patients against the coronavirus.

These ATLAS community members are joined by members of several other campus groups who are also 3D printing face-shield parts, including the Idea Forge, the Integrated Teaching & Learning Program, the Program in Environmental Design, CU Science Discovery, the Department of Aerospace Engineering, Department of Physics, the Laboratory for Atmospheric and Space Physics and the BEEM Lab in Mechanical Engineering, said Rebecca Komarek, assistant director of Idea Forge and a coordinator for campus face shield production with the statewide Make4Covid initiative. As of April 14, Make4Covid reported it had delivered nearly 11,750 pieces of equipment, including more than 1,400 face shields made by CU Boulder groups.

Seltzer and Pascente originally collaborated with the NoCo Face Shield Project, a volunteer organization building protective face shields for Northern Colorado healthcare facilities, delivering their first batch of parts on March 28 to the Fort Collins Creator Hub. More recently, NoCo has joined forces with Make4Covid, which means a lot less driving. In an attempt to speed up print times, Pascente and Seltzer are beginning to experiment with larger nozzles for their 3D printers.

Between Pascente, Seltzer and Weaver, who have been at this longer than the others, they have manufactured parts for roughly 400 shields. Weaver, who is focusing on making completed face shields, cutting his own visors by hand from thin sheets of transparent plastic, has finished about 100, including a dozen delivered to Wardenburg Health Center on the CU Boulder campus. Seltzer and Pascente are printing headbands and curved plastic reinforcements that attach to the top and bottom of transparent visors. “The focus is to print a lot of parts and get them to people who are assembling and distributing them,” said Seltzer.

The minimal design many of the makers are using originated with physicians who collaborated with the Czech Republic Ministry of Health and 3D printer manufacturer Prusa.

“As one of many people making parts at home 24/7, I'm glad to be contributing to this project,” Seltzer said.

Other ATLAS coronavirus-related projects:

Instructions for making a simple "no-sew" mask, by CTD student Ruhan Yang