FGBA

Coca-Cola in Space

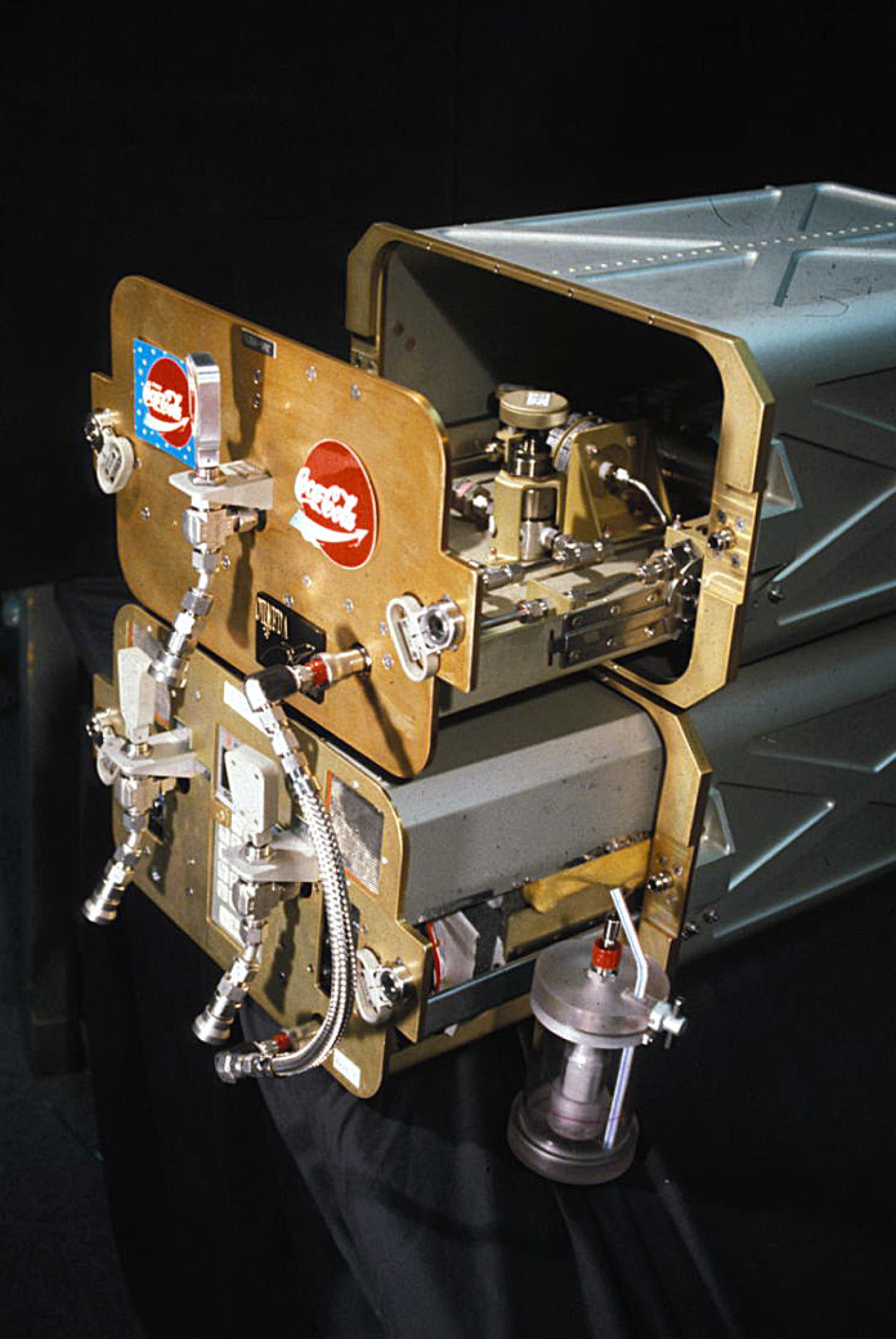

The Fluid Generic Bioprocessing Apparatus (FGBA) was developed by BioServe in partnership with the Coca-Cola Company between 1994 and 1996. The basic function of FGBA was to dispense Coca-Cola products for astronaut consumption and enjoyment. Beyond that, FGBA served a very pertinent role in validating engineering techniques for the containment, manipulation, and transfer of supersaturated two-phase fluids in microgravity which was a relatively uncharacterized problem at the time and is a significant challenge outside of just carbonated beverages. These advances ultimately led to a US patent being granted for the technology used in FGBA. Additionally, the Coca-Cola Company had scientific objectives in characterizing changes in taste perception in space and applying that information to better understand natural changes in taste perception that occur on Earth due to aging and disease. FGBA even included an integral heart rate monitor to track astronauts' physiological reactions.

FGBA-1 flew on STS-63 in 1995 and featured a dual middeck locker design that could dispense both Coke and Diet Coke. The beverages were stored in a carbonated state and kept cool prior to dispensing. This mission was also the first flight of the Fluids Transfer Unit (FTU) which was essentially a pressurized bottle with specialized geometry that prevented CO2 from disassociating from the Coke under unpressurized microgravity conditions. The FTU was equipped with a straw that astronauts could use to drink from it.

FGBA-2 flew on STS-77 in 1996 and featured an integrated dual middeck locker design that could dispense Powerade in addition to Coke and Diet Coke. The payload featured a touchscreen interface allowing astronauts to adjust parameters to achieve ideal dispensation such as temperature and CO2 ratio. A notable design objective of FGBA-2 was to demonstrate that carbonated beverages could be mixed in microgravity using just syrup, water, and a pressurized CO2 supply. This methodology mirrors the same basic process used in soda fountains on Earth. After some on-orbit troubleshooting due to excessive foam formation, FGBA-2 ultimately proved that the technology was feasible and the astronauts on STS-77 were able to enjoy the "made from scratch" Coca-Cola products.

Nowadays, FGBA-1 can be found at the World of Coca-Cola museum in Atlanta, GA and FGBA-2 can be found at the Astronaut Hall of Fame at KSC.