That lightbulb represents more than just a good idea

Top image: dreamstime.com

In research recently published in Science, CU Boulder scientists detail how light—rather than energy-intensive heat—can efficiently and sustainably catalyze chemical transformations

For many people, the role that manufactured chemicals plays in their lives—whether they’re aware of it or not—may begin first thing in the morning. That paint on the bedroom walls? It contains manufactured chemicals.

From there, manufactured chemicals may show up in prescription medicine, in the bowls containing breakfast, in the key fob that unlocks the car, in the road they take to work. These products are so ubiquitous that it’s hard to envision life without them.

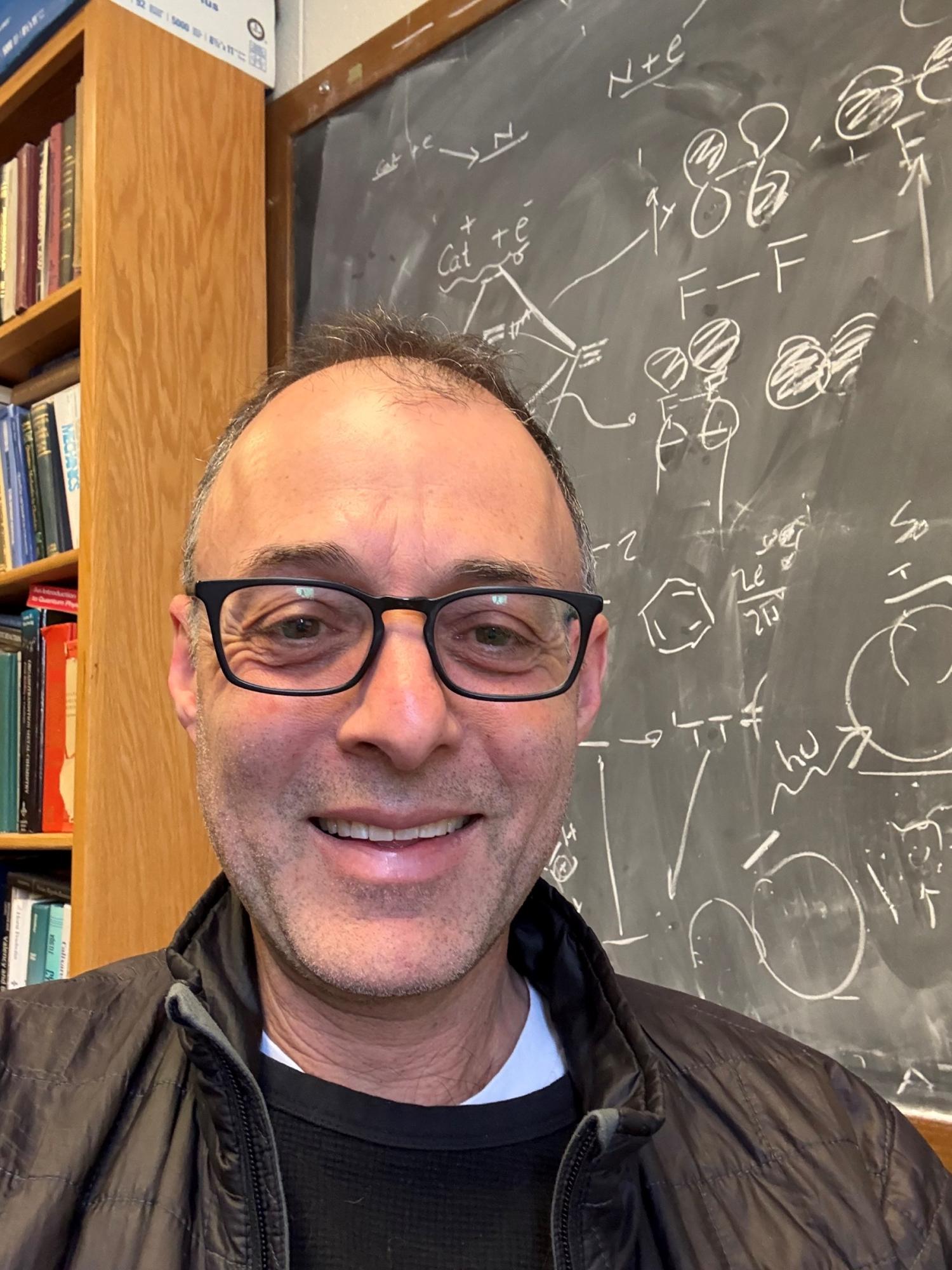

Professor Niels Damrauer and his CU Boulder and CSU research colleagues were inspired by photosynthesis in designing a system using LED lights to catalyze transformations commonly used in chemical manufacturing.

The process of transforming base materials into these desired products, however, has long come at significant environmental cost. Historically, catalyzing transformations in industrial processes has frequently used extreme heat to create the necessary energy.

Now, continuing to build on a growing body of research and discovery, University of Colorado Boulder scientists are many steps closer to using light instead of heat to catalyze transformations in industrial processes.

In a study recently published in Science, Niels Damrauer, a CU Boulder professor of chemistry and Renewable and Sustainable Energy Institute fellow, and his research colleagues at CU Boulder and Colorado State University found that a system using LED lights can catalyze transformations commonly used in chemical manufacturing. And it’s entirely possible, Damrauer says, that sunlight could ultimately be the light source in this system.

“With many transformations, the economics are, ‘Well, I need this product and I’m going to sell it at this price, so my energy costs can’t be larger than this amount to make a profit’,” Damrauer says. “But when you start to think about climate change and start to think about trying to create more efficient ways to make things, you need different approaches.

“You can do that chemistry with very harsh conditions, but those harsh conditions demand energy use. The particular chemistry we are able to do in this paper suggests we’ve figured out a way to do these transformations under mild conditions.”

Inspired by plants

Damrauer and his colleagues—including first authors Arindam Sau, a CU Boulder PhD candidate in chemistry, and Amreen Bains, a postdoctoral scholar in chemistry at Colorado State University in the group of Professor Garret Miyake—work in a branch of chemistry called photoredox catalysis, “where ‘photo’ means light and ‘redox’ means reduction and oxidation,” Damrauer explains. “This type of chemistry is fundamentally inspired by photosynthesis. A lot of chemistry—not all of chemistry, but a huge fraction of chemistry—involves the movement of electrons out of things and into other things to make transformations. That happens in plants, and it happens in photoredox catalysis as well.

“In photosynthesis, there’s a beautiful control over not only the motion of electrons but the motion of protons. It’s in the coupling of those two motions that a plant derives functions it’s able to achieve in taking electrons out of something like water and storing it in CO2 as something like sugar.”

Further inspired by photosynthesis and a plant’s use of chlorophyl to collect sunlight, the research team used an organic dye molecule as a sort of “pre-catalyst” that absorbs light and transforms into a catalyst molecule, which also absorbs light and accelerates chemical reactions. And because the four LED lights surrounding the reactor are only slightly brighter than a regular home LED lightbulb, the transformation process happens at room temperature rather than extreme heat.

The molecule is also able to “reset” itself afterward and harvest more light, beginning the process anew.

“In photosynthesis, there’s a beautiful control over not only the motion of electrons but the motion of protons. It’s in the coupling of those two motions that a plant derives functions it’s able to achieve in taking electrons out of something like water and storing it in CO2 as something like sugar,” says CU Boulder researcher Niels Damrauer.

“We set out to understand the behavior of a photocatalyst that was inefficient at this process, and my student Arindam discovered there was this fundamental transformation to the molecule occurring while we did the reaction,” Damrauer says, adding that the team discovered there are key motions not just of electrons, which is essential for photoredox, but also of protons.

“In our mechanism, the motion of the proton occurs in the formation of a water molecule, and that very stable molecule prevents another event that would undermine the storage of energy that we’re trying to achieve,” Damrauer says. “We figured out what the reaction was and, based on that reaction, we started to make simpler molecules.

“This was a really fortuitous discovery process: We were studying something, saw a change, took the knowledge of what that change was and started to design systems that were even better. This is the best advertisement for basic science—sometimes you can’t design it; you’ve got to discover things, you’ve got to have that freedom.”

A sunny future

Damrauer, Sau and their colleagues in the multidisciplinary, multi-institutional Sustainable Photoredox Catalysis Research Center (SuPRCat) are continuing to build on these discoveries, which happen at a small scale now but may have the potential for large-scale commercial use.

In an essay for The Conversation, Sau noted, “Our work points toward a future where chemicals are made using light instead of heat. For example, our catalyst can turn benzene—a simple component of crude oil—into a form called cyclohexadienes. This is a key step in making the building blocks for nylon. Improving this part of the process could reduce the carbon footprint of nylon production.

“Imagine manufacturers using LED reactors or even sunlight to power the production of essential chemicals. LEDs still use electricity, but they need far less energy compared with the traditional heating methods used in chemical manufacturing. As we scale things up, we’re also figuring out ways to harness sunlight directly, making the entire process even more sustainable and energy efficient.”

Damrauer adds that he and his colleagues aren’t trying to change the nature of manufactured chemicals, but the approach to how they’re made. “We’re not looking at making more stable paint, for example, but we’re asking if it costs a certain number of joules to make that gallon of paint, how can we reduce that?”

In addition to Niels Damrauer, Arindam Sau and Amreen Bains, Brandon Portela, Kajal Kajal, Alexander Green, Anna Wolff, Ludovic Patin, Robert Paton and Garret Miyake contributed to this research.

Did you enjoy this article? Subscribe to our newsletter. Passionate about chemistry? Show your support.