Senior Design

Senior Design is a transitional experience—preparing students for an entry level engineering position. The experience emulates industry, allowing students to apply and deploy the engineering knowledge learned over their course of study to a real-world, open-ended design challenge. Through this experience students will come to realize the complete cycle of design from conceptual design to hardware/software testing, and then repeating the cycle.

Actual hardware/software will be produced, and students will understand the difference between theory, paper, and actual materials. Students gain valuable connections and are mentored by a dedicated industry professional in addition to a biomedical engineering faculty advisor. Students will gain the professional skills necessary to succeed in industry and in life! Senior Design is perhaps the ultimate expression of engineering, and the "heart and soul" of applied science!

Objectives

Teamwork

Understand how to work collaboratively toward a common goal

Technical Skills

Integrate course knowledge, acquire project-specific knowledge and resource management

Design and Process Skills

Gain proficiency in design and application of design process

Communication

Gain written and oral proficiency in technical and professional communication

Project Management

Learn how to manage long-term projects

Professionalism

Gain professional skills

Past Senior Design Projects

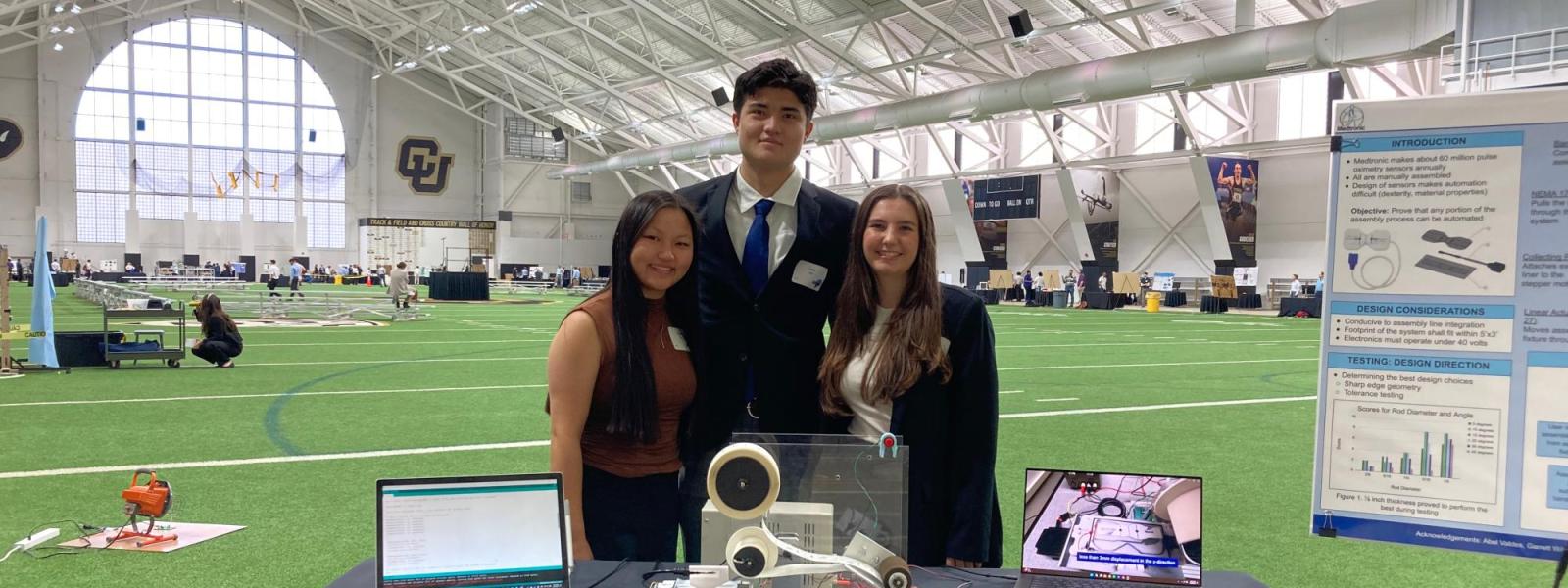

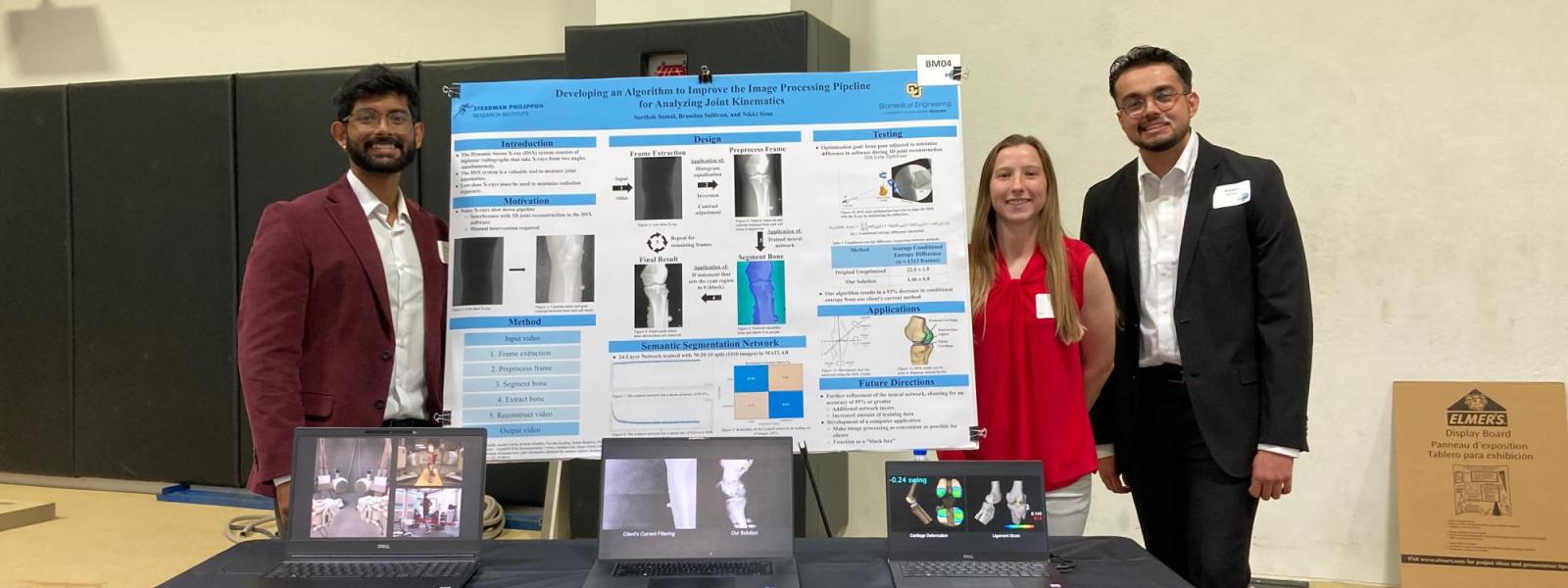

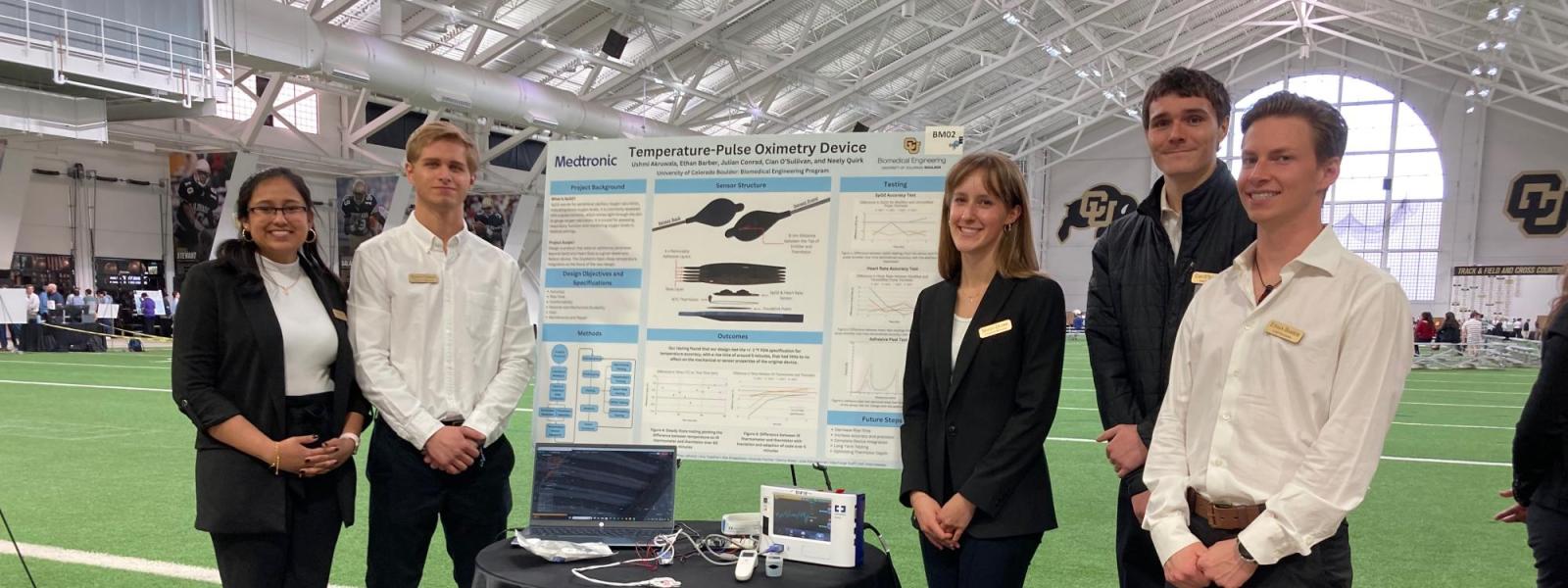

CU Boulder Engineering Expo

This large-scale exposition in the spring celebrates the work of all the engineering students completing their senior design projects that is open to the public.

2026 Senior Design Projects

Team Members: Danny Vo, Rachel Zamora, Payton Campbell, Aishna Kumari, Suhani Amin, Kori Johnson

Project Sponsor: CONMED

Team Breathing Buffs is designing a dynamic, volume-changing anatomical test cavity for CONMED's AirSeal Insufflation System. By simulating realistc surgical conditions, such as breathing and coughing, this device will provide novel ways to evaluate insufflator performance, which may lead to improved patient outcomes.

Team Members: Cassie Eisen, Anna Sallee, Sara Wissner, David Debretsion, Matteo Coscia, Nathan Day, Alyssa Radman

Project Sponsor: Project S.E.R.V.E.

Team BuffaloHIDE (Heated Integrated Device for Extremeties) is partnering with Project S.E.R.V.E. to develop a residual limb warmer for winter para-athletes. Designed for all-day use before, during, and after competition, this device will help prevent discomfort, injury, and long-term complications in cold-exposed residual limbs.

Team Members: Oliver Snidow, Merci Schneider, Julia Hollenbach, Christopher Garrington, Aidan Jambor, Surina Gidha, Haley Liu

Project Sponsor: Cardiost, Inc.

Team El Capitan is designing a left ventricular assist device to improve the quality of life and outcomes for patients with Heart Failure with Preserved Ejection Fraction (HFpEF). Working with Cardiost, Inc., this team is optimizing the mechanical system to provide the necessary fluid transport in a safe and energy-efficient manner.

Team Members: Maeve Binh, Maddie Venezia-Ford, Meredith Overton, Alena Tucker, Ben Finneseth, Aryan Mulgaokar

Project Sponsor: Shine Music

Team Eye Tunes is working with Shine Music to design a set of closed caption glasses for use at live music events by individuals who are deaf or hard of hearing. This device will bring a new level of accessibility to concerts, theater, lectures, and beyond.

Team Members: Brendan Cotter, Gabe Wu, Katie Fleming, Karisma Leung, Vivian Nguyen, Estelle Kennamer, Mella Strand

Description coming soon.

Team Members: Avery Deringer, Anaelle Dutat, Charlotte Rindfuss, Emma Keesey, Zoe Zeidler

Project Sponsor:

Team Insolemates is developing a wearable sensor for children to detect toe walking, a gait abnormality that can cause joint discomforn, pain, and long-term complications. This device will help children, caretakers, and physicians to monitor walking habits on an every day basis, bringing personalized medicine to the playground.

Team Members: Kevin Leidig, Charlie Kunha, Izzy Racine, Raul Luevano, Iris Li, Sudhiksha Sivakumar

Project Sponsor: CranioRehab

Team JawesomeByte is working with CranioRehab to develop a jaw pressure and opening measurement device to aid in accurate sizing of dental implants and improved rehabilitation protocols for temporomandibular joint (TMJ) surgery. Building upon CranioRehab's OraStretch Press, this device will be a useful research and treatment tool for provideres such as providers, such as surgeons and speech language pathologists.

Team Members: Matteo Campbell, Aidan McAdoo, Aleah Farac, Tanvi Rami, Hayes Griffin, Alisha Kumari

Project Sponsor: TissueForm

Team KneedIt is partnering with TissueForm to design a device to effectively deliver cartilage tissue paste during arthroscopic surgery. In addition to improving upon the state of care in arthroscopic settings, this device will help bring novel biomaterials to other surgical settings in orthopedics facial/cosmetic surgery.

Team Members: Sophia Water, Allie Garner-Hall, Kaitlin Norris, Jameson Parks, Atanas Dimitrov

Project Sponsor: TissueForm

Team MILC is developing a custom sterile package for TissueForm to store and deliver their novel biomaterial for use in arthroscopic surgery. Targeting FDA approval, this team is optimizing their packaging design to balance sterility, rigidity, and scalability.

Team Members: Cody Campos, Savannah Presson, Madison Voytko, Kady Vu, Rohan Gohil, Breeana Pritchard

Project Sponsor: CaliberMRI, Inc.

Team Mr. I is developing a biomimetic imaging phantom for quantitative MRI. In partnership with CaliberMRI, Inc., this team is designing anatomically realistic models that can be 3D printed and modified to reflect different tissue properties under MRI. This device will provide a novel method to calibrate MRI systems.

Team Members: Beata Wolak, Cheranne Wang, Yoni Bereket, Landon Stampka, Conall Soon, Hamza Ahmed

Project Sponsor: FullBodySound

Team ParallelSound is working with FullBodySound to continue development on a multiuser method for full body electrostimulation, for use at entertainment and therapeutic settings. Combining music signals with electrostimulation, this device will provide a novel, immersive way to enjoy music and increase acceessibility at live music venues.

Team Members: Mallory Phillips, Madison Kuo, Abi Johnson, St. John Tsuno-Wayne, Vivian Shi, Natalie Carpenter, Cara Colwell

Surgical Handling of Advanced Robotic Procedure (SHARP) Description coming soon.