Equipment and Techniques

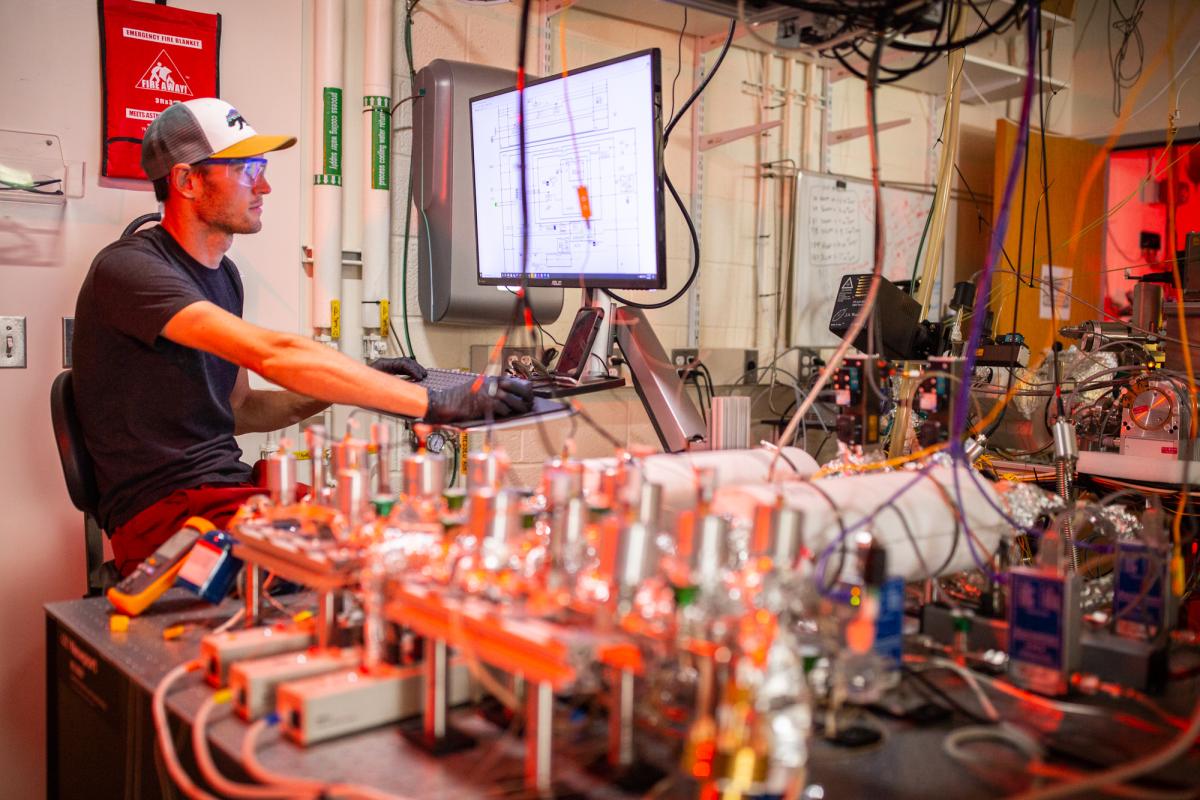

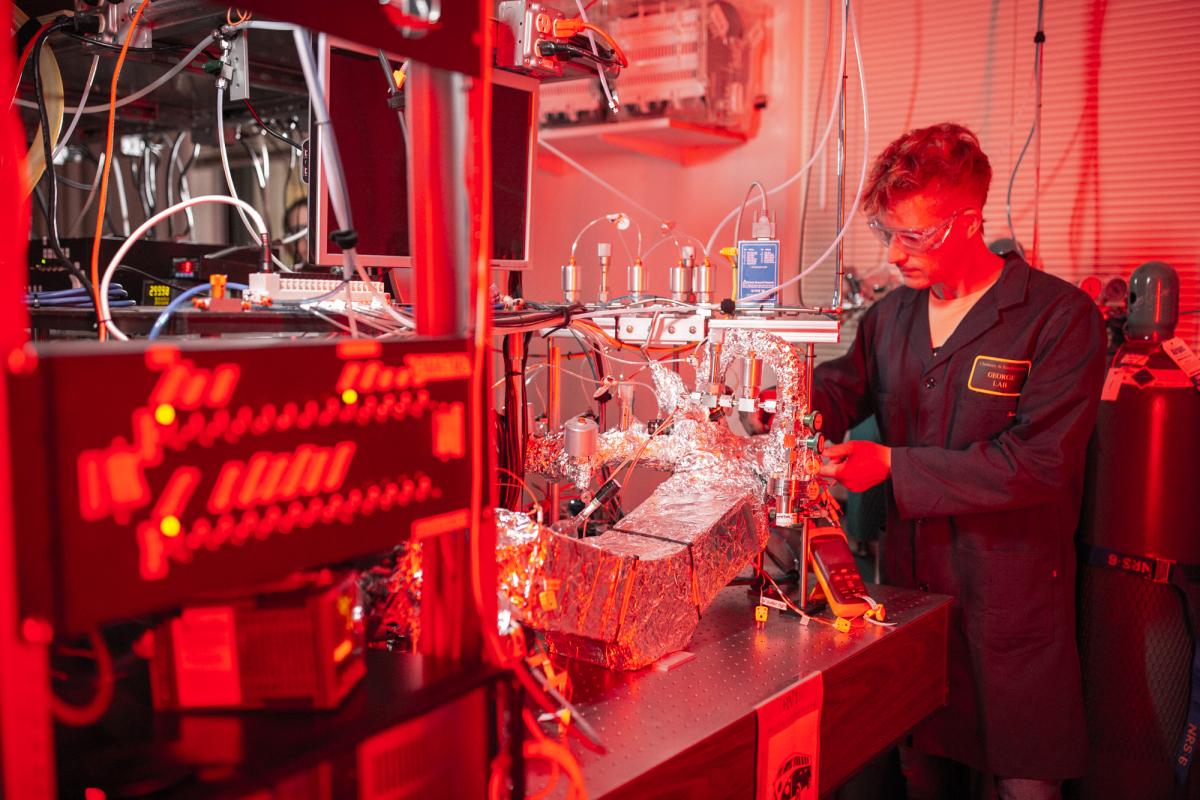

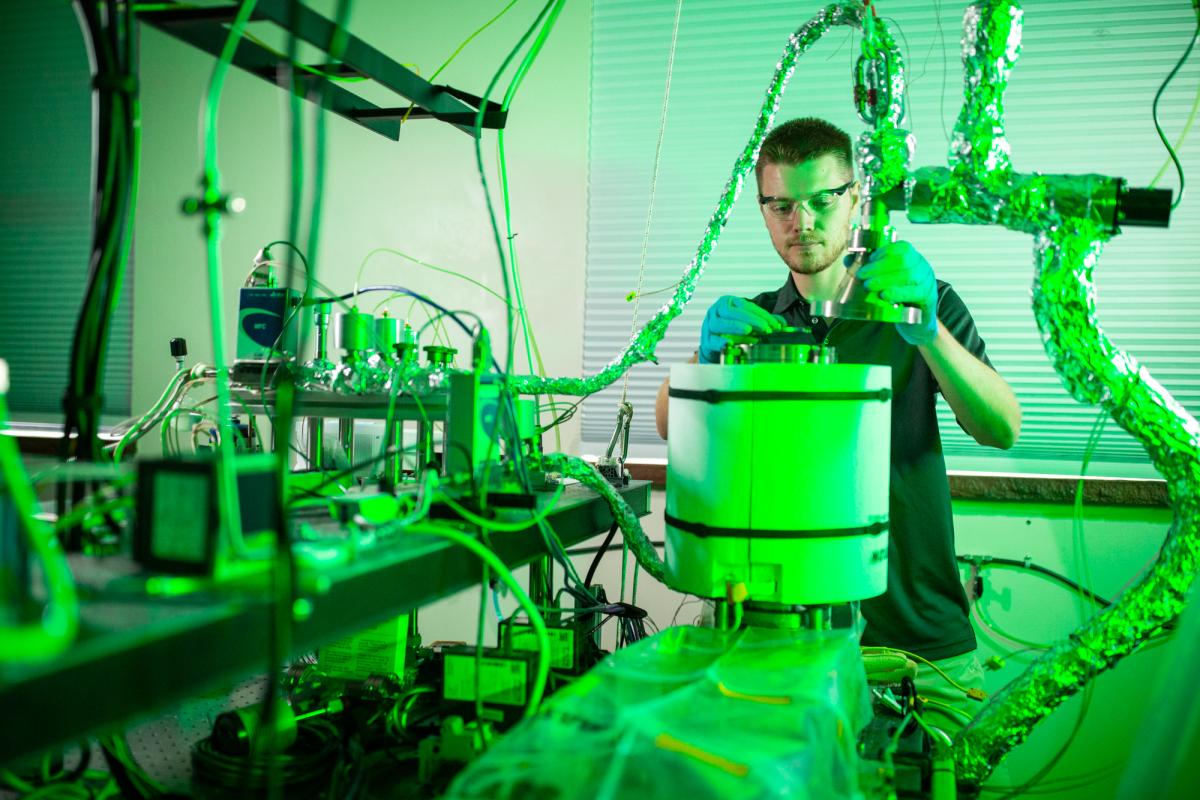

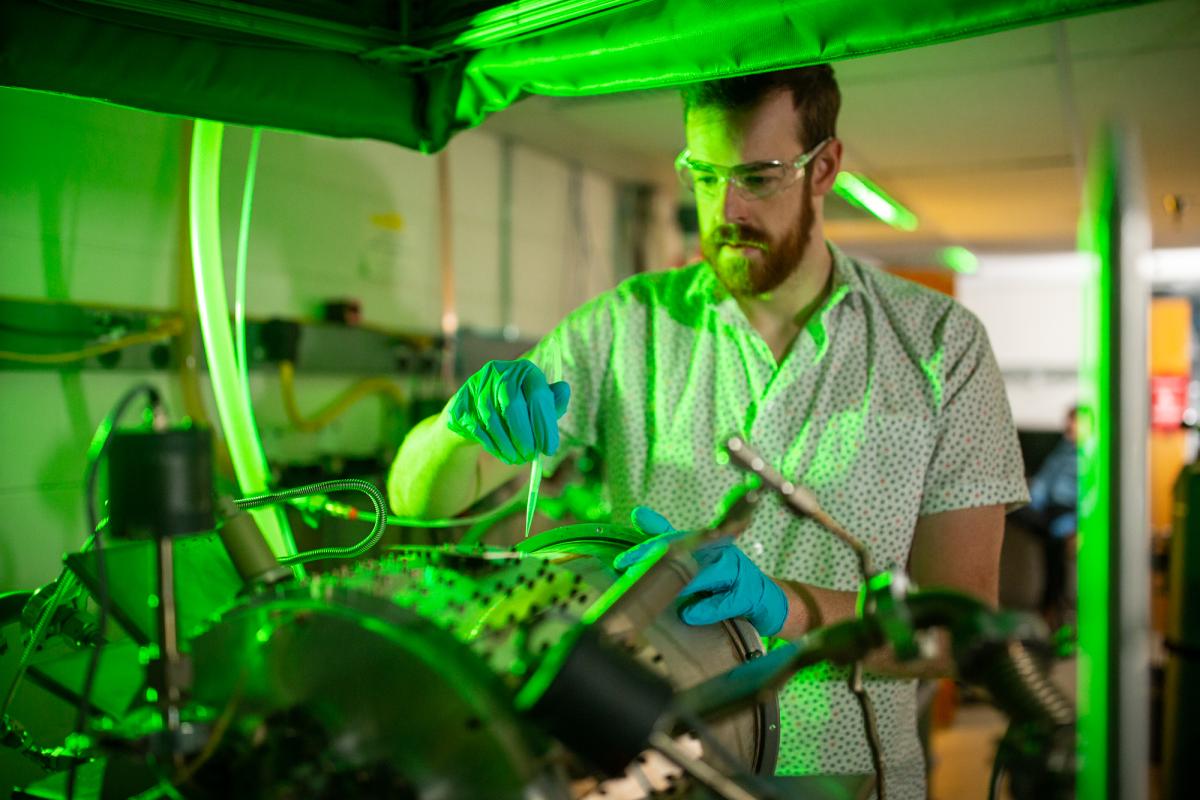

The Steven M. George research group is well equipped to study surface chemistry, thin-film growth and etching, and thin-film properties. Many of these studies are focused on atomic layer deposition (ALD), atomic layer etching (ALE), and molecular layer deposition (MLD). Thin-film growth and etching investigations using ALD, ALE, and MLD are conducted in a variety of home-built reactors. Some of these analyses are performed in situ during thin-film growth and etching. Other studies are conducted ex situ after removing the sample from the reactor. All of the techniques and equipment described below are available within the research group.

The reactors in the group currently include:

5 Hot wall viscous flow reactors equipped with an in situ quartz crystal microbalance (QCM) to monitor film growth and etching. One of these reactors can accommodate 8” wafers.

1 Hot wall viscous flow reactor equipped for in situ Fourier transform infrared (FTIR) investigations of film growth and etching.

1 Hot wall viscous flow reactors for routine growth and etching without in situ probing techniques. One of these reactors can accommodate 6” wafers.

1 Plasma ALD reactor equipped with an in situ spectroscopic ellipsometer.

2 Hot wall rotary reactors for coating or etching particles using ALD/MLD or ALE.

1 Hot wall open-ended rotary reactor equipped with a plasma source for coating or etching particles.

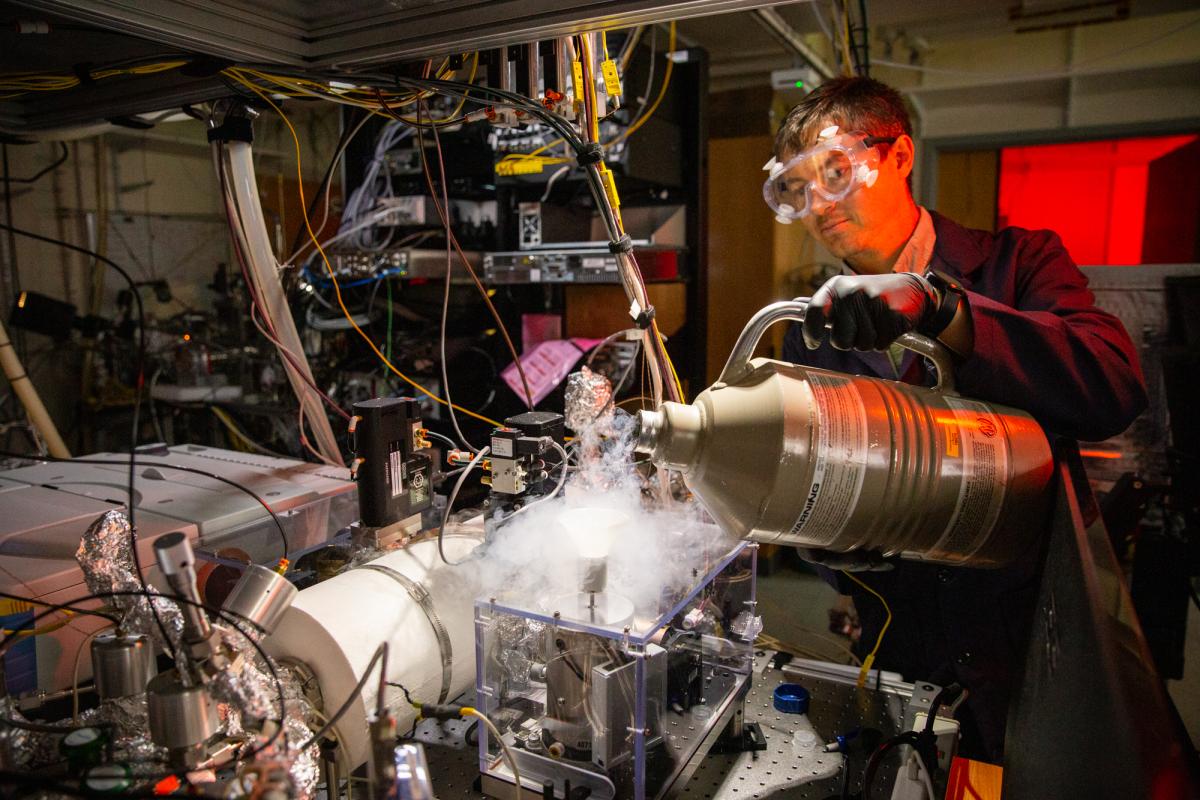

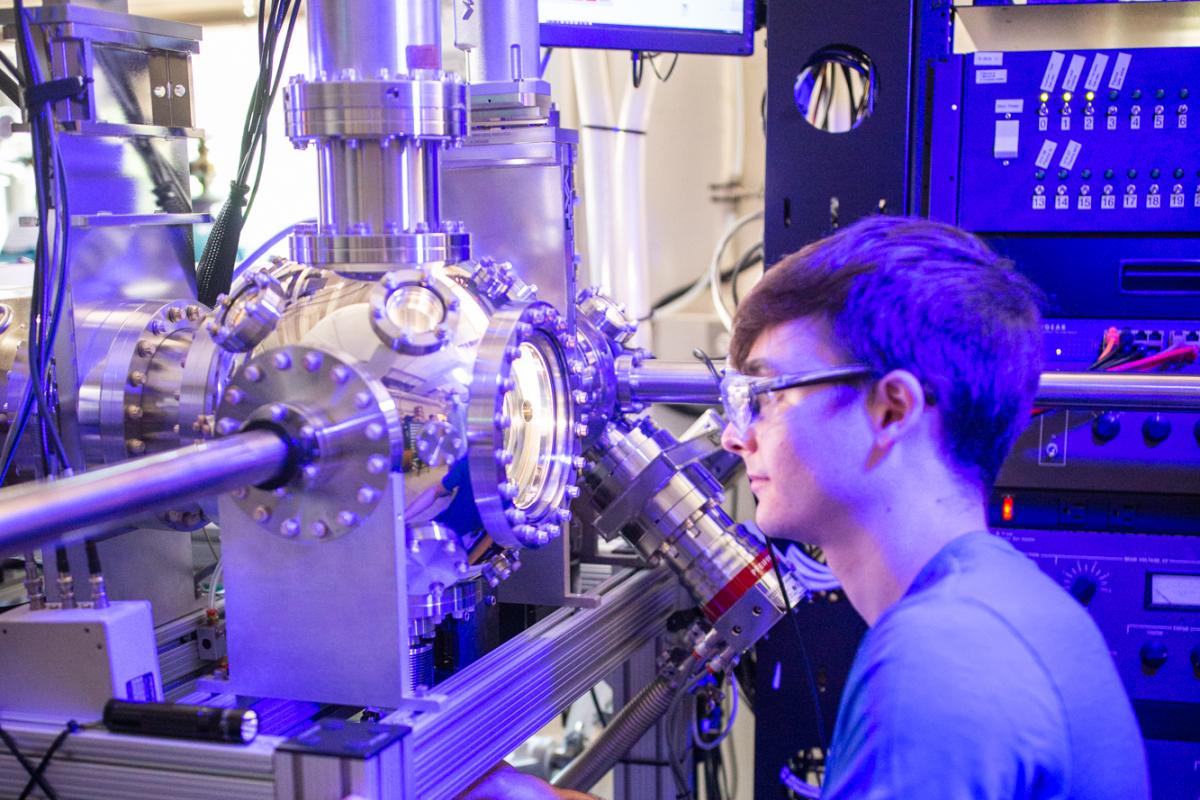

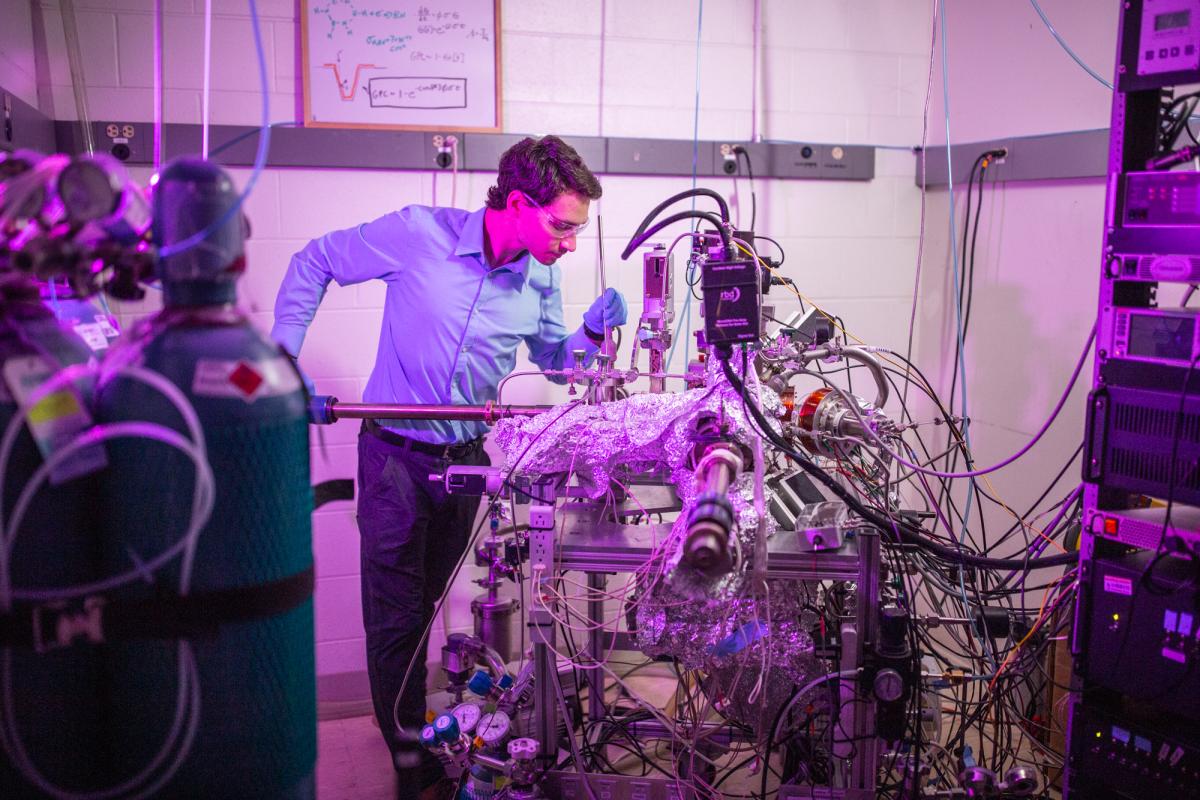

1 UHV ALD reactor equipped with an electron gun for electron-stimulated desorption to promote ALD growth at low temperature.

1 Spatial ALD reactor equipped with a plasma electron source for electron-stimulated desorption to promote ALD growth on flat 6” substrates at low temperature.

2 Rotating cylinder spatial ALD/MLD reactors for depositing on flexible substrates and extendable to roll-to-roll processing.

Hot-wall viscous-flow reactors with in situ quartz crystal microbalances (QCM) anre used for measuring mass change due to ALD or ALE.

Hot-wall viscous-flow reactors with in situ spectroscopic ellipsometers are used for monitoring film thickness during deposition and etch.

Surface species are monitored during ALD, ALE or MLD using a vacuum chamber designed for in situ Fourier-Transform Infrared (FTIR) spectroscopy studies. High surface area particles provide sufficient surface sensitivity for transmission FTIR experiments. Vibrational spectroscopy reveals the gain and loss of surface species during the two surface half-reactions. The vibrational absorbance of the material either grows during ALD/MLD or is lost during ALE.

Quadrupole mass spectrometry (QMS) is utilized as an in situ probe on several ALD/E process chamber in the group.

On viscous flow reactors for ALD, ALE and MLD - When employed to sample reactor pressures of 1-10 Torr, the mass spectrometer is differentially-pumped using a turbomolecular pump.

Molecular beams of atom layer etch products - QMS is used to monitor the products of ALE in a custom built, multistage molecular beam systems.

Residual gas analysis in the high vacuum chambers - Mass spectrometers are located on the XPS spectrometer and the UHV ALD reactor equipped with an electron gun for electron-stimulated desorption.

An in situ multi beam optical sensor is used to measure film induced mechanical stress by monitoring the changes in the radius of curvature of wafers during deposition and etch.

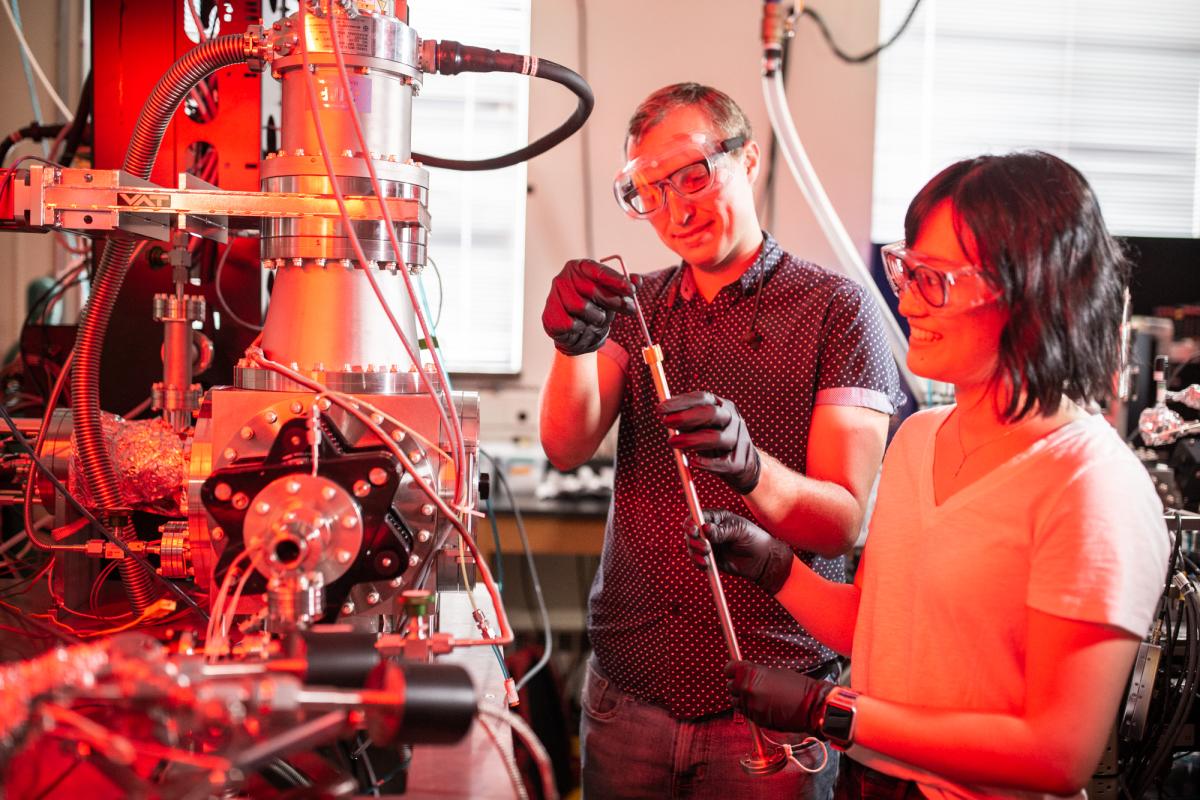

Two deposition/etch systems are designed for the transfer samples under vacuum from a process chamber (~1 Torr) to a UHV chamber (~10-10 Torr) for analysis with Auger electron spectroscopy (AES).

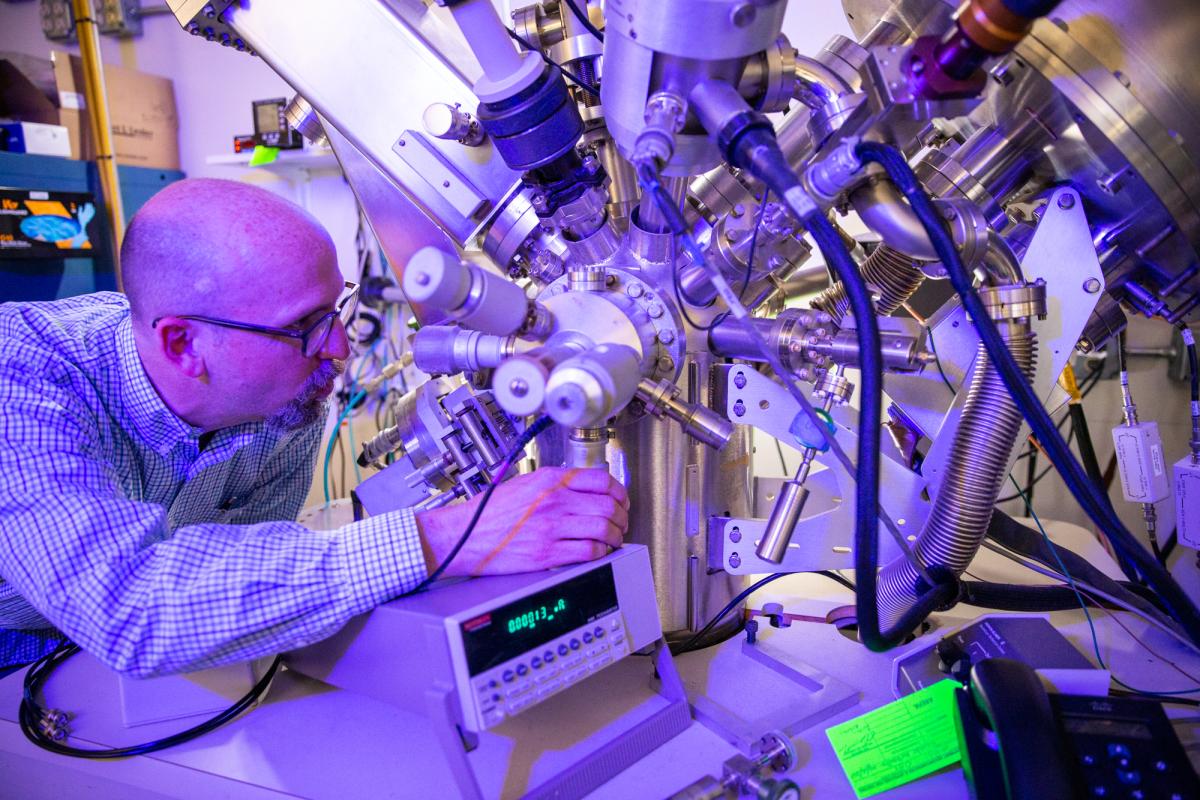

Electron enhanced ALD (EE-ALD) uses a beam of electrons to stimulate the desorption of surface species to generate reactive surface sites for film deposition. EE-ALD chambers in the group are equipped with a variety fo tools for in situ analysis including Auger electron spectroscopy, quadrupole mass spectrometry, spectroscopic ellipsometry, and retarding field electron energy analysis.

Spatial ALD/ALE/MLD in conducted on flexible substrates in a rotating drum reactor or a Roll-2-Roll reactor. 150 mm wafers are processed with spatial ALD in a third reactor.

ALD/ALE/MLD are carrried out on particles in a rotary reactor.

Physical vapor deposition is carried out with a two source magnetron system enabled for DC and RF. This systems allows for vacuum sample transfer to an ALD/ALE chamber with spectroscopic ellipsomtry and in situ Kelvin probe measurements.

In situ quartz crystal microbalance (QCM) measurements are employed to monitor ALD, ALE and MLD in viscous flow reactors. The QCMs from Inficon/Maxtek have exceptional mass sensitivity and the mass changes for each reaction are able to unravel the stoichiometry of the surface reactions. The growth/etching of the film is also determined by the linear mass increase/decrease versus the AB reaction cycles. In situ QCM measurements are utilized in nine hot wall viscous flow reactors.

The composition and chemical state information of thin films is obtained using a PHI 5600 x-ray photoelectron spectroscopy (XPS) system. This PHI 5600 XPS system has both a standard x-ray source and a monochromatic x-ray source. The monochromatic x-ray source is needed for analyzing organic and polymeric samples. The PHI 5600 is equipped with a sputter gun for depth-profiling the samples. The angle of the sample can also be adjusted to obtain depth-profile information.

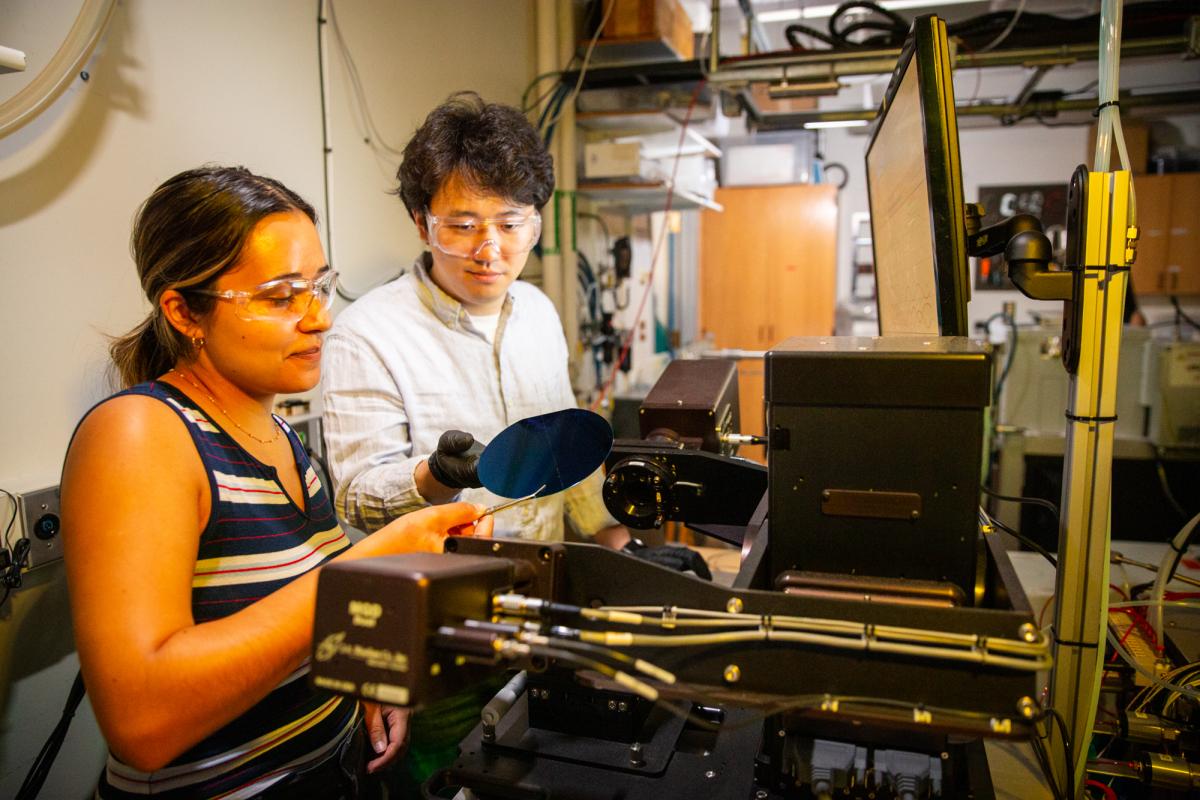

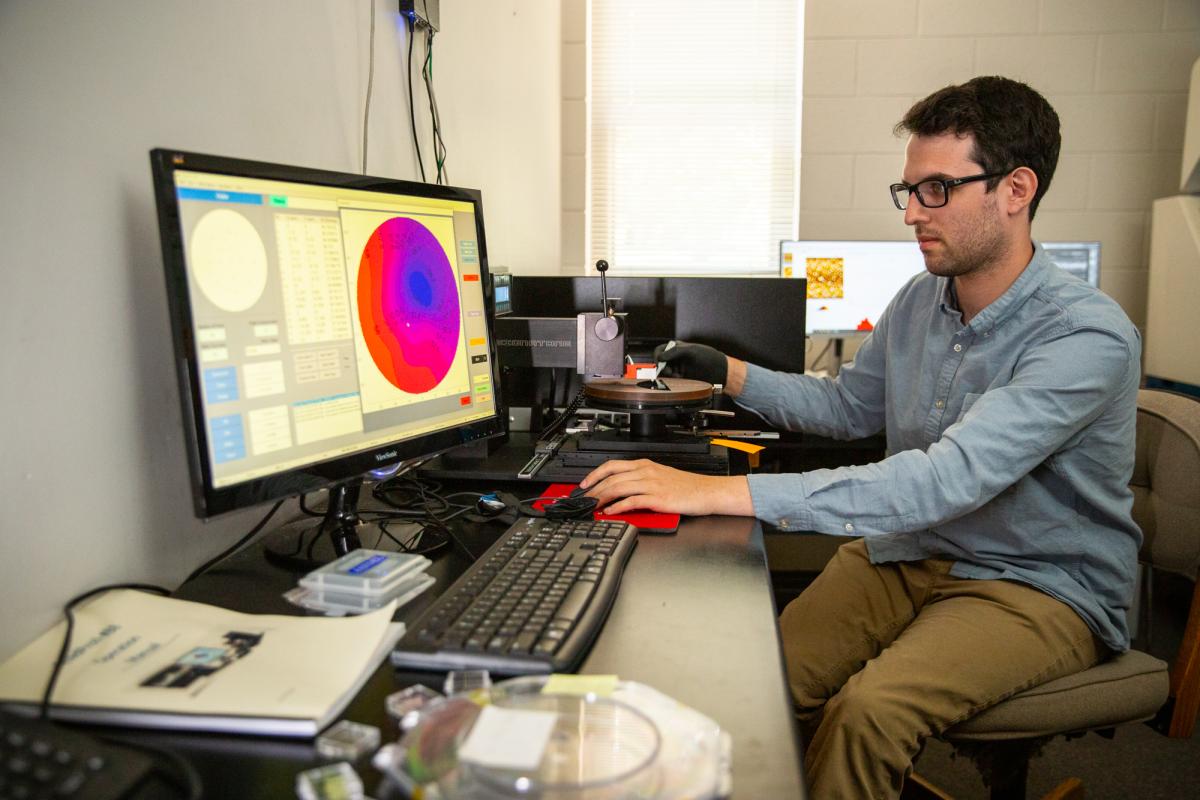

Film thicknesses and optical parameters, such as the refractive index and extinction coefficient, can be measured using spectroscopic ellipsometry. The group uses several M-2000 and iSE instruments from the J.A. Woollam Company. One of the M-2000 ellipsometers is configured for automized measurements at variable incident angles (VASE). This setup can also employ focusing optics to obtain spot sizes of 300 µm. The other instruments are mounted on several ALD, ALE, and MLD reactors to monitor nucleation and growth or etching in situ.

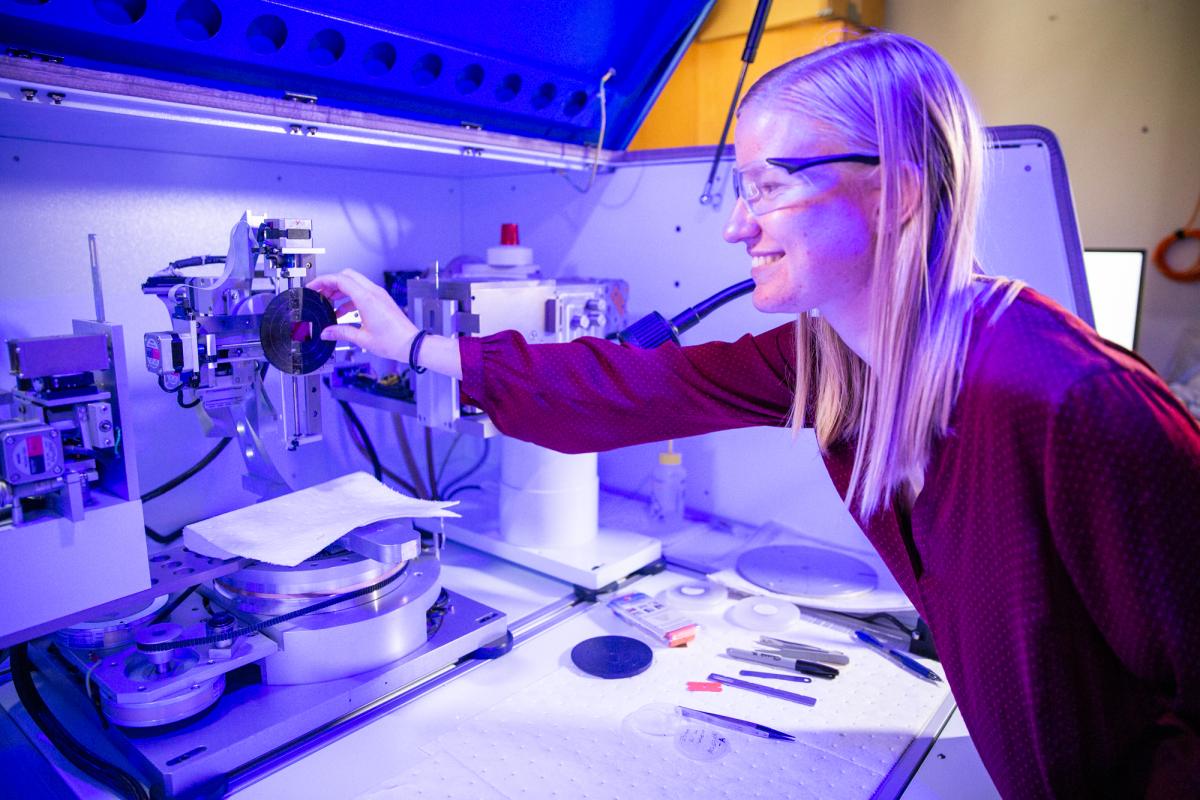

The research group utilizes a Bede D1 x-ray diffractometer (XRD) that is optimized for x-ray reflectivity (XRR) of thin films and nanolaminates. XRD is important for structural characterization and crystalline alignment. XRR is very useful to evaluate film thickness, film density and interfacial roughness. XRR is especially valuable in characterizing superlattices and nanolaminates.

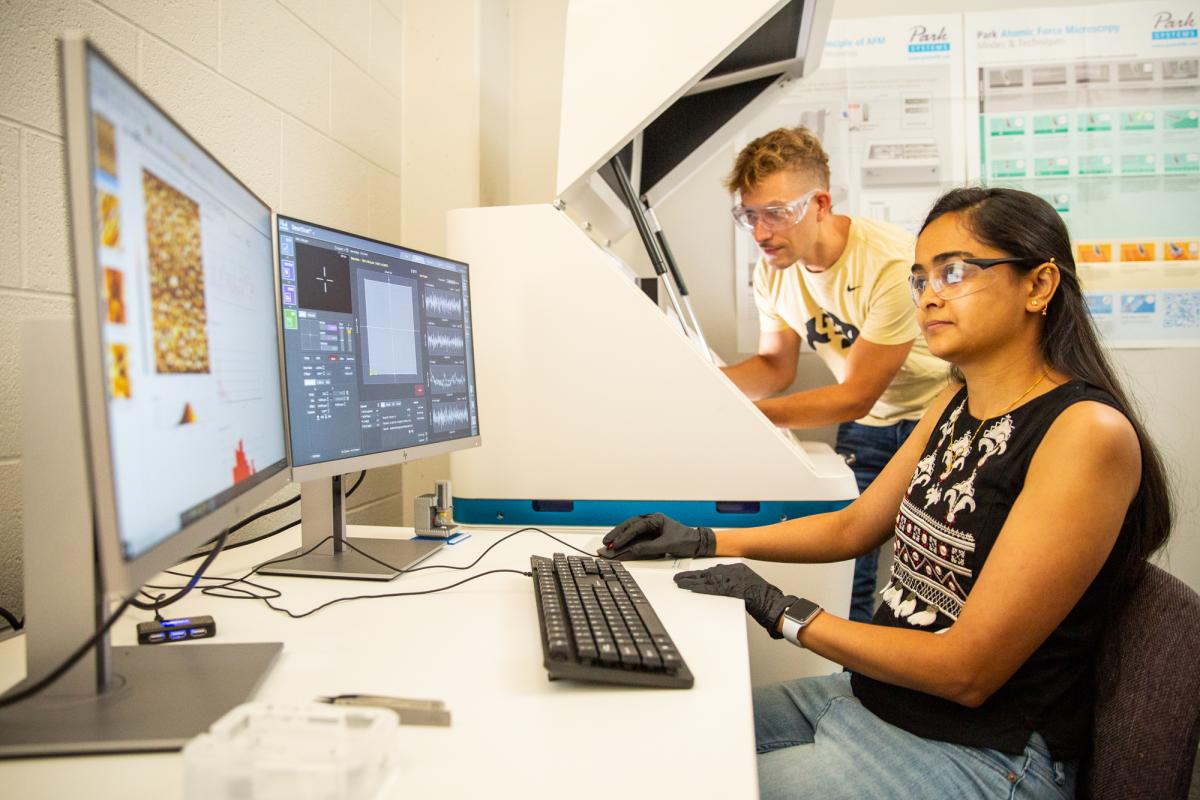

Atomic force microscopy (AFM)

Thin-film conductivity can be measured using an ex situ 4-point probe from Signatone. In addition, an in situ 4-point probe has been developed to measure film conductivity during ALD. This 4-point probe can monitor ALD growth during sequential reactant exposures.

The research group maintains a gas leak detection station to evaluate the vacuum quality of the reactors and vacuum chambers. The gas leaks are detected using a quadrupole mass spectrometer that is differentially-pumped by a turbomolecular pump. This gas leak detection station is portable and can easily be moved throughout the laboratory.

The research group has a glove box from Vacuum Atmospheres that is attached to the PVD chamber. This glove box allows oxygen-sensitive films to be removed from the PVD chamber without air exposure. A hot wall ALD reactor is also attached to the glove box and allows the oxygen-sensitive films to be transferred directly into the ALD reactor without air exposure.

Polymer films are prepared using a spin coater that can deposit polymer films on silicon wafers or QCM sensors. The research group has a dedicated spin coater from Laurell that has facilitated our research on polymers.

Membrane Gas-Permeation & Desalination Test

The ALD or MLD film growth or ALE film removal can be determined using ex situ surface profilometry. The profilometer obtains the film thickness by measuring the step height between the deposited/etched film and an area that was masked using tape or photoresist. The research group uses a Dektak 3 surface profilometer.

The current-voltage (IV) and capacitance-voltage (CV) properties of insulating films can be characterized using a Hg-probe from the Materials Development Corporation (MDC). This Hg-probe has been used to study the Fowler-Nordheim tunneling behavior of Al2O3 ALD films that may have application for high k capacitors and gates.

The research group maintains an environmental test chamber from Espec that can control temperature and H2O relative humidity. This environmental test chamber is used to maintain the conditions during measurement of water vapor transmission rates (WVTRs).

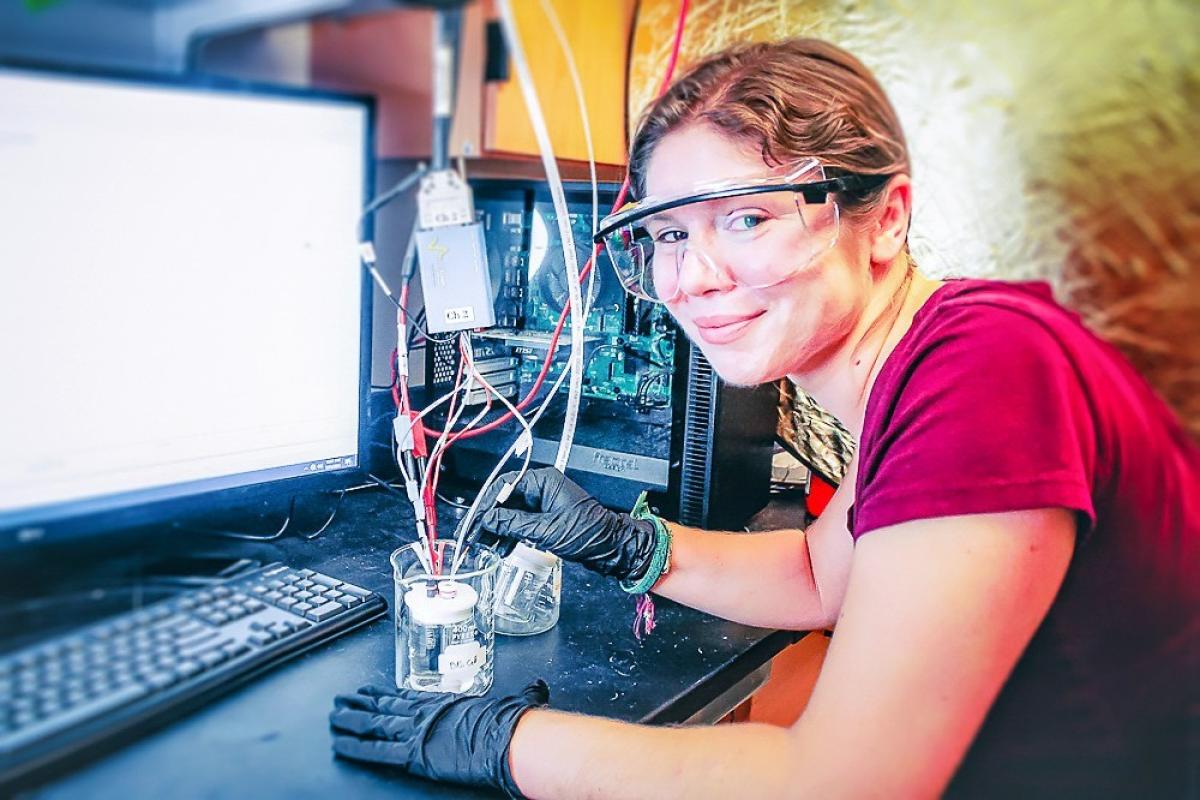

The group has a potentiostat/galvanostat/EIS analyzer (BioLogic SP-300) for electrochemical analysis of Li ion battery and pseudocapacitance material. In addition, the group recently obtained an Arbin Instruments MSTAT4 for repetitive charge/discharge analysis of Li ion battery material.