Evaluation of Gate Valve Flanges: Serrated vs Non-Serrated Under External Loading

Project Title: Evaluation of Gate Valve Flanges: Serrated vs Non-Serrated Under External Loading

Industry Partners: Denver Water

CIEST Personnel: Cory Ihnotic and Jessica Ramos

Primary Investigator: Prof. Brad Wham

Year: 2024

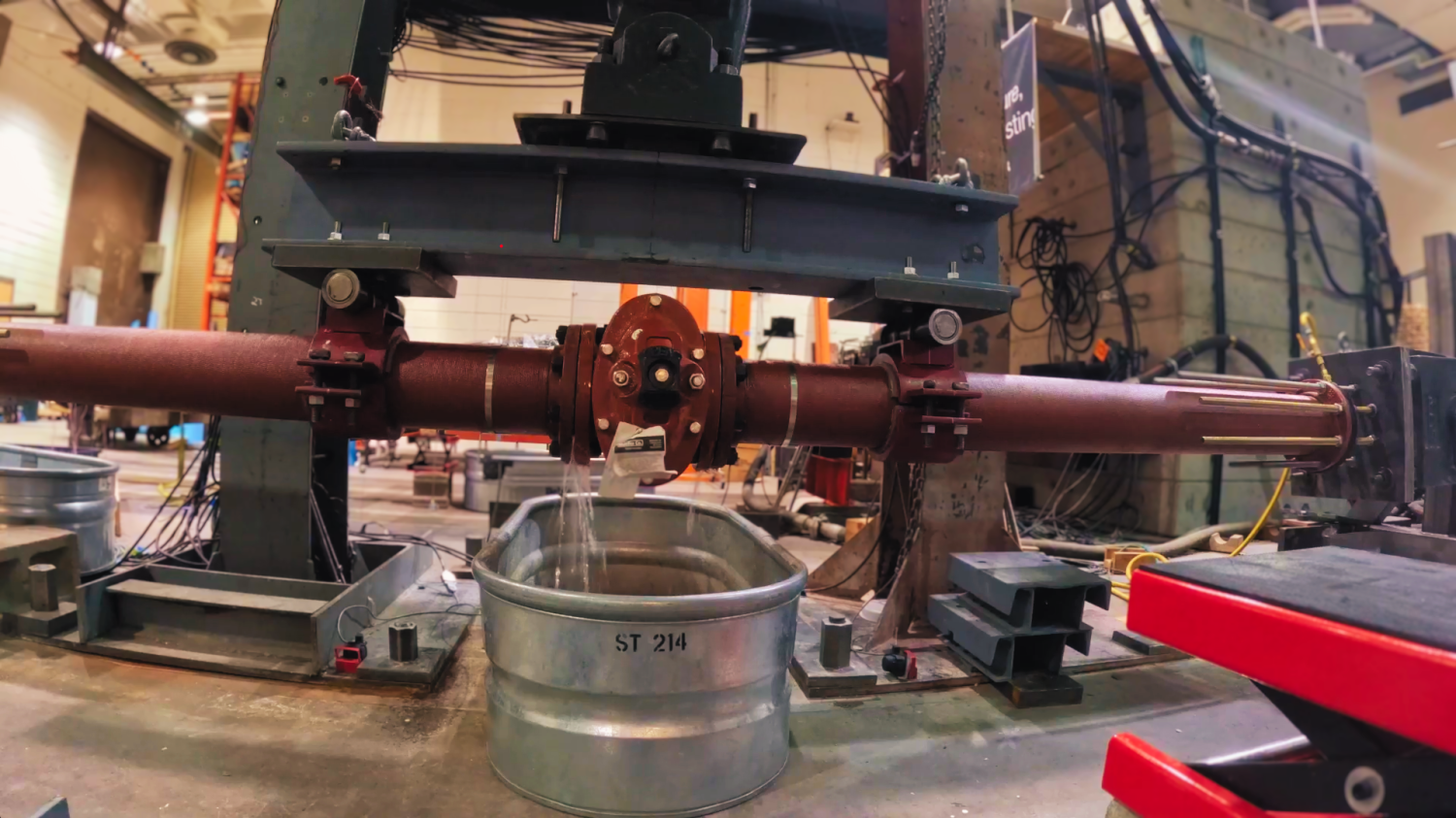

The intent of this study is to investigate the difference between a serrated faced flange connection and a non-serrated faced flange connection; mainly to determine whether one would leak sooner than the other. To evaluate this, a series of four-point bending tests with applied axial load were conducted on Mueller Resilient Wedge Gate Valves. The tested specimens were commercially available 6 in. (150 mm) diameter ductile iron pipe conforming to AWWA C600 standards, which were provided by Denver Water. Each type of flange connection (serrated or non-serrated) received two tests, each with displacement applied at a rate of 1 in. (25 mm) per minute. For the conducted tests, several points of interest were located including the site of the first and second leaks, and their respective leak rates to determine which of the connections had a more substantial failure.

Appreciation is extended to John Daly and Katie Ross, along with all our pipe and coupling manufacturers, for their tremendous support.

Link to testing report: https://www.colorado.edu/center/ciest/sites/default/files/2025-03/240820%20DW-Serrated%20vs%20Nonserrated__Final%20Draft_v2.pdf