Advancing super strong and lightweight next generation carbon-based materials

Materials researchers are getting a big boost from a new database created by a team of researchers led by Hendrik Heinz.

A professor of chemical and biological engineering at the University of Colorado Boulder, Heinz advanced a major initiative to create a public database, available online to all researchers, that contains over 2,000 carbon nanotube stress-strain curves and failure properties.

“This data sharing is important. It allows the scientific community to build on and expand. Instead of someone spending a year figuring out the mechanics of a particular carbon nanostructure in experiments, they can use this database. You’ll have the results in one hour,” said Heinz, who is also a faculty member in the materials science and engineering program.

The announcement came in a new paper published in the Proceedings of the National Academy of Sciences.

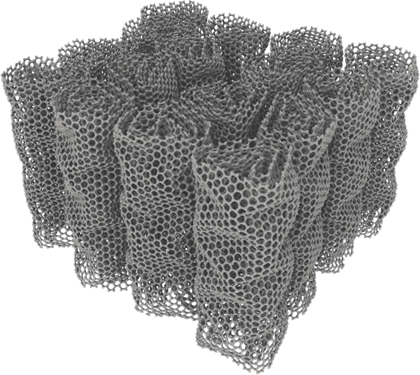

Carbon nanotubes and associated graphitic structures are strong and lightweight engineered materials with great potential in multiple sectors, including aviation, automobiles, and electronics. They were first discovered in the 1970s, but their tiny size – the engineering is conducted at the atomic scale – has made them difficult to study, until now.

“Carbon nanotubes and graphene can be stronger than steel,” Heinz said. “They will be really important for next generation cars, planes, and spacecraft, but we have to understand their chemistry and physics.”

Working with a team that included researchers from the Air Force Research Laboratory, Johns Hopkins University, Texas A&M University, and the University of California San Diego, the group built computational models using artificial intelligence to develop high quality predictions of mechanical properties of different carbon nanotube materials.

How will a stress-strain and failure database assist researchers? With any material, it is necessary for product designers to understand their strength and ability to withstand adverse conditions and manipulation.

“This is a problem where data science was really able to help. Materials science usually has a problem of sparse data and not enough data points. This model changes that. Now someone can take a 3-dimensional structure and change the morphology or introduce a defect and it will be really easy to test,” Heinz said.

The project grew out of a National Science Foundation initiative called “Harnessing the Data Revolution” and represents six years of research.

“People have made claims that they had a 3D structures database for carbon nanotubes, but they had no attached mechanical properties or conductivity or anything useful,” Heinz said “You can’t learn anything from that. This is the first database structures and the properties, and it’s available to a broad community."

The database is available on both figShare and Github.

In addition to Heinz, co-authors of the PNAS paper include Jordan Winetrout (MatSciPhD’24) from CU Boulder; Professor Yusu Wang, Zilu Li, and Qi Zhao, all from UCSD; Assistant Professor Vinu Unnikrishnan and Landon Gaber from Texas A&M University; Vikas Varshney from AFRL; and Associate Professor Yanxun Xu from Johns Hopkins University.