Optimal decision making in robotic assembly and other trial-and-error tasks

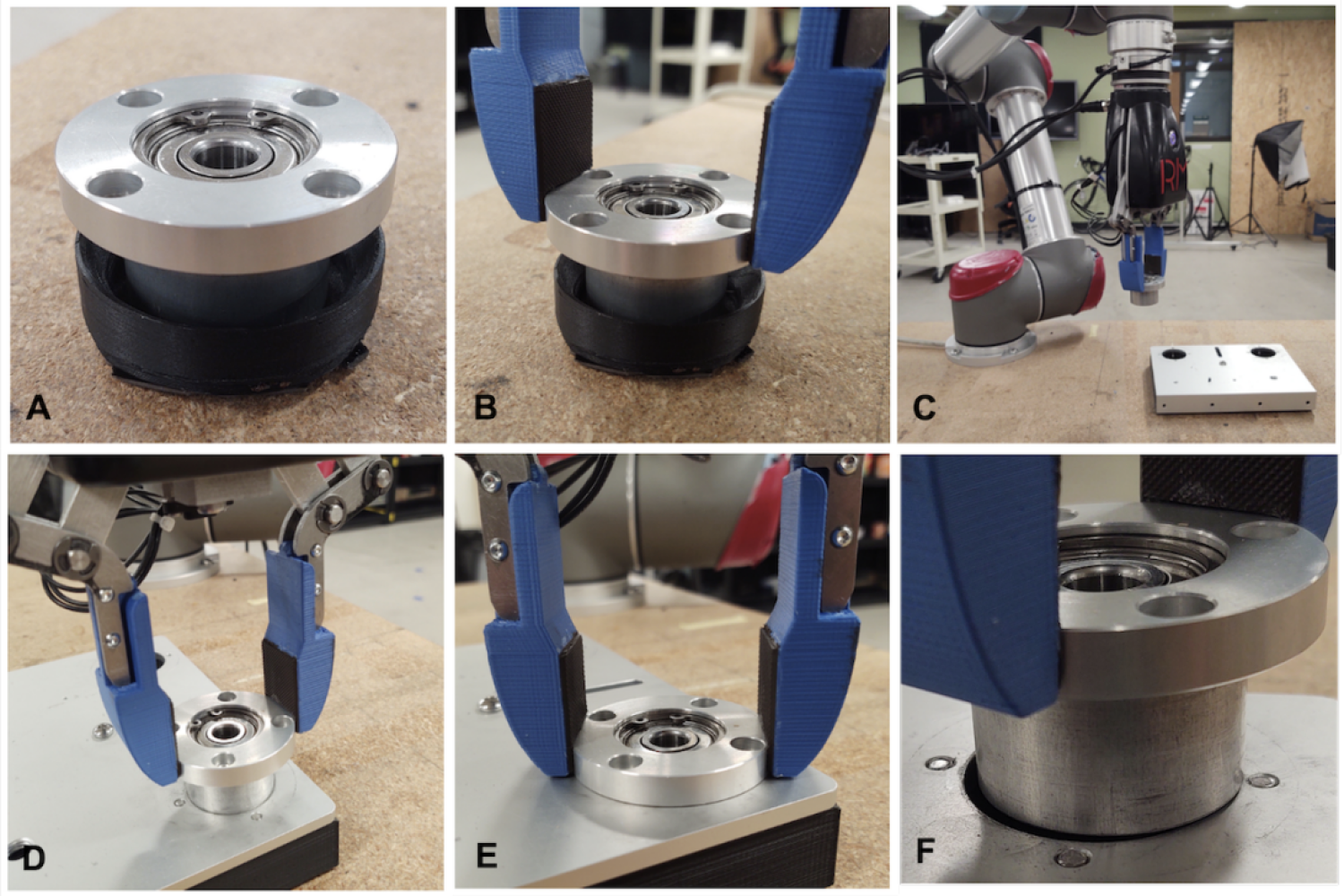

Uncertainty in perception, actuation, and the environment often require multiple attempts for a robotic task to be successful. We study a class of problems providing (1) low-entropy indicators of terminal success / failure, and (2) unreliable (high-entropy) data to predict the final outcome of an ongoing task. Examples include a robot trying to connect with a charging station, parallel parking, or assembling a tightly-fitting part. The ability to restart after predicting failure early, versus simply running to failure, can significantly decrease the makespan, that is, the total time to completion, with the drawback of potentially short-cutting an otherwise successful operation. Assuming task running times to be Poisson distributed, and using a Markov Jump process to capture the dynamics of the underlying Markov Decision Process, we derive a closed form solution that predicts makespan based on the confusion matrix of the failure predictor. This allows the robot to learn failure prediction in a production environment, and only adopt a preemptive policy when it actually saves time. We demonstrate this approach using a robotic peg-in-hole assembly problem using a real robotic system. Failures are predicted by a dilated convolutional network based on force-torque data, showing an average makespan reduction from 101s to 81s (N=120, p<0.05). We posit that the proposed algorithm generalizes to any robotic behavior with an unambiguous terminal reward, with wide ranging applications on how robots can learn and improve their behaviors in the wild.

References

Watson, J. and Correll, N., 2023. Optimal decision making in robotic assembly and other trial-and-error tasks. Int. Conf. on Intelligent Robots and Systems (IROS), Detroit, MI.