Research

Slected publication

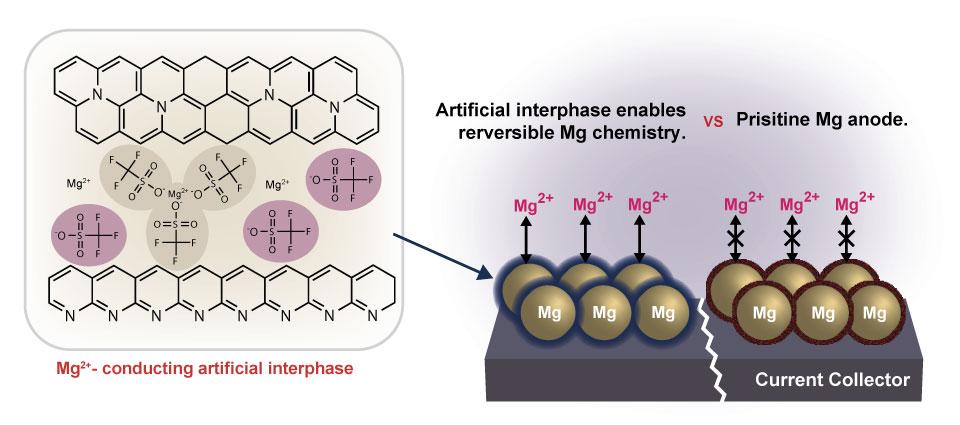

By engineering a Mg2+-conductive artificial interphase on the Mg surface, we demonstrate highly reversible Mg deposition/stripping in the oxidation-resistant, carbonate-based electrolytes. The artificial interphase even enables the reversible Mg/V2O5full-cell cycling in the water added electrolyte.

NatureChemistry, 2018

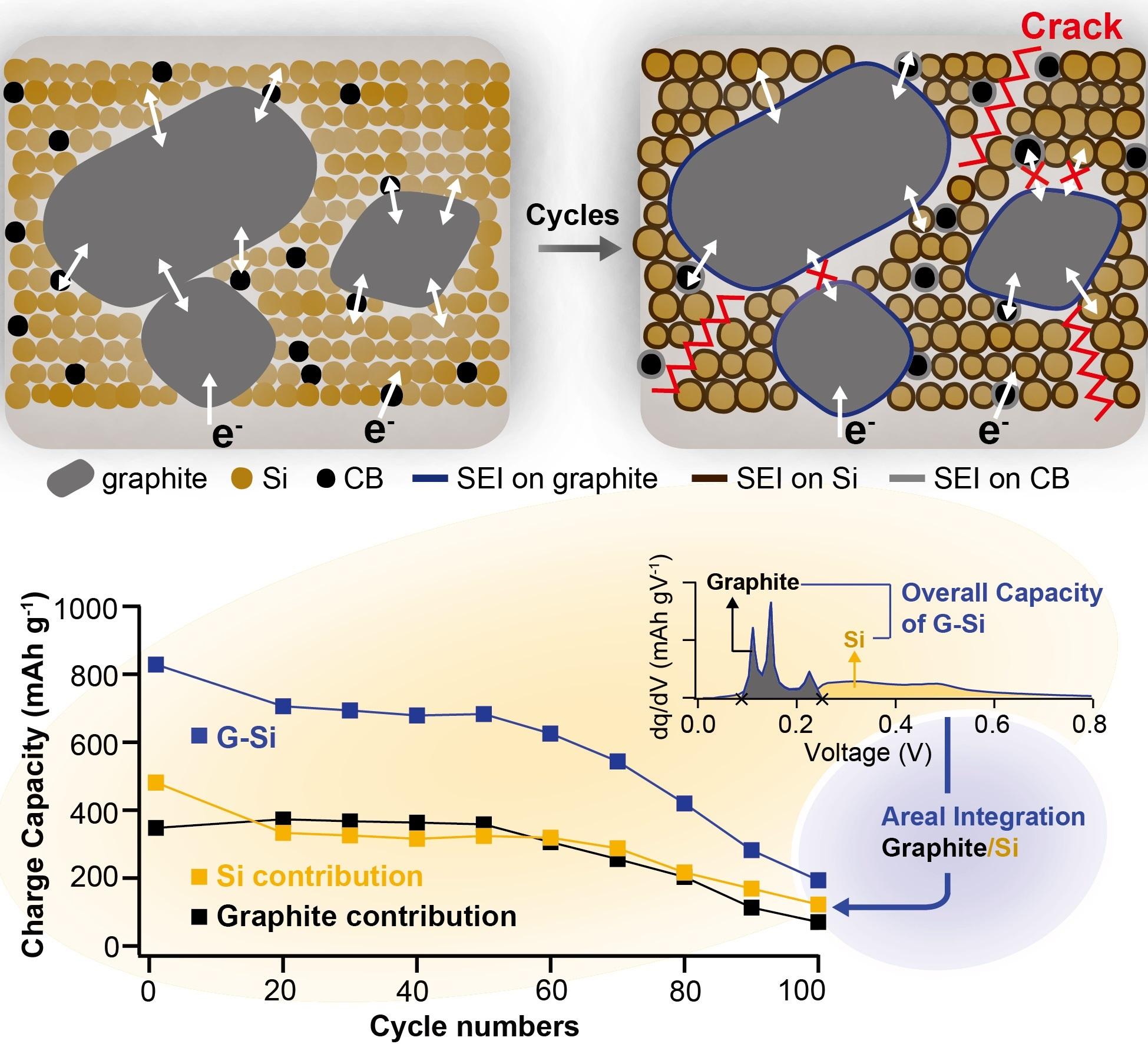

Established a methodology comprising differential plots and integral calculus to analyze the failure mechanism underlying capacity fade of composite graphite-Si electrode.

Adv. Science. 2018

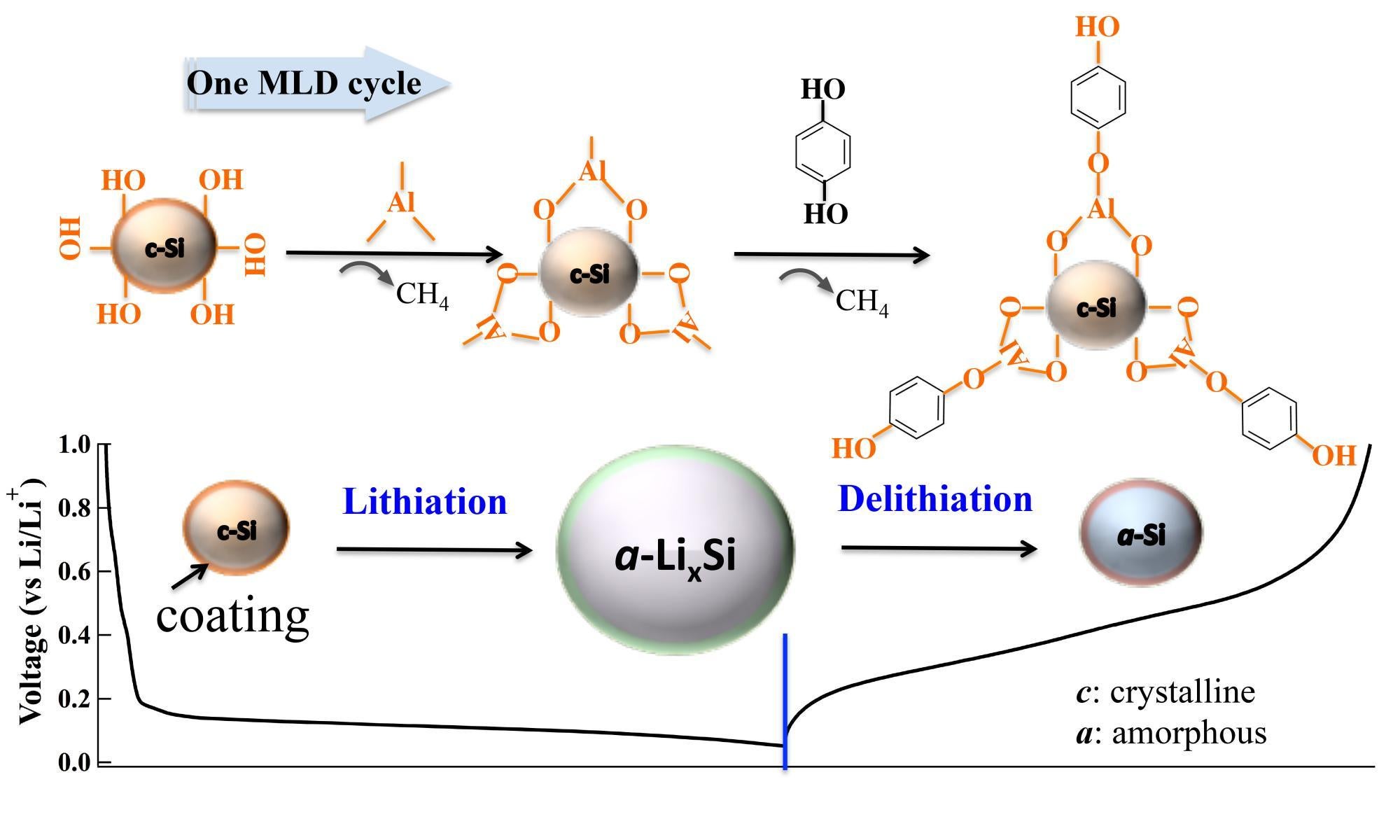

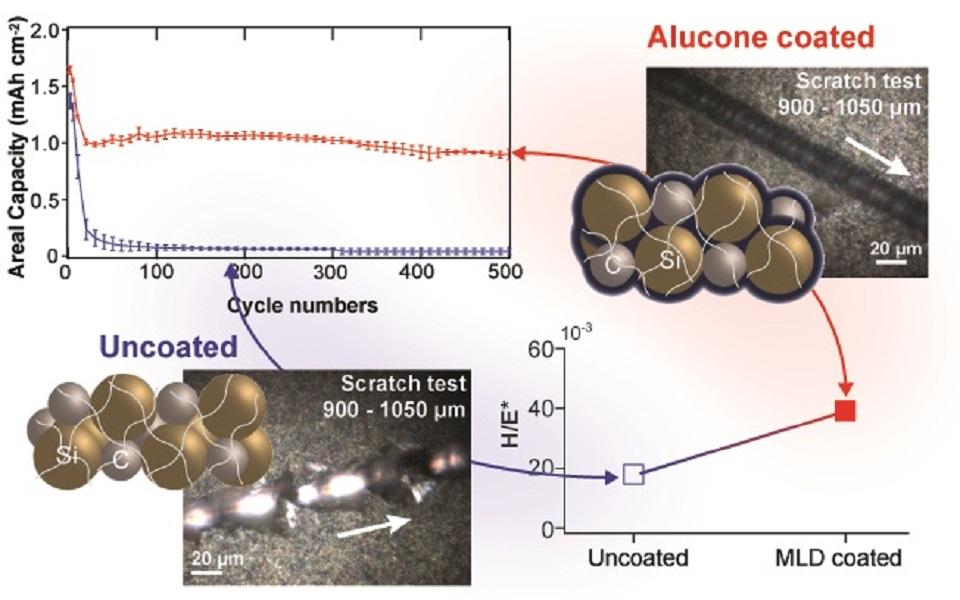

The schematic of MLDcoating for the Si-basedmaterials (top) and theelectrochemical lithiationanddelithiationof thecoated materials (bottom).

Nano Energy 22, 2016

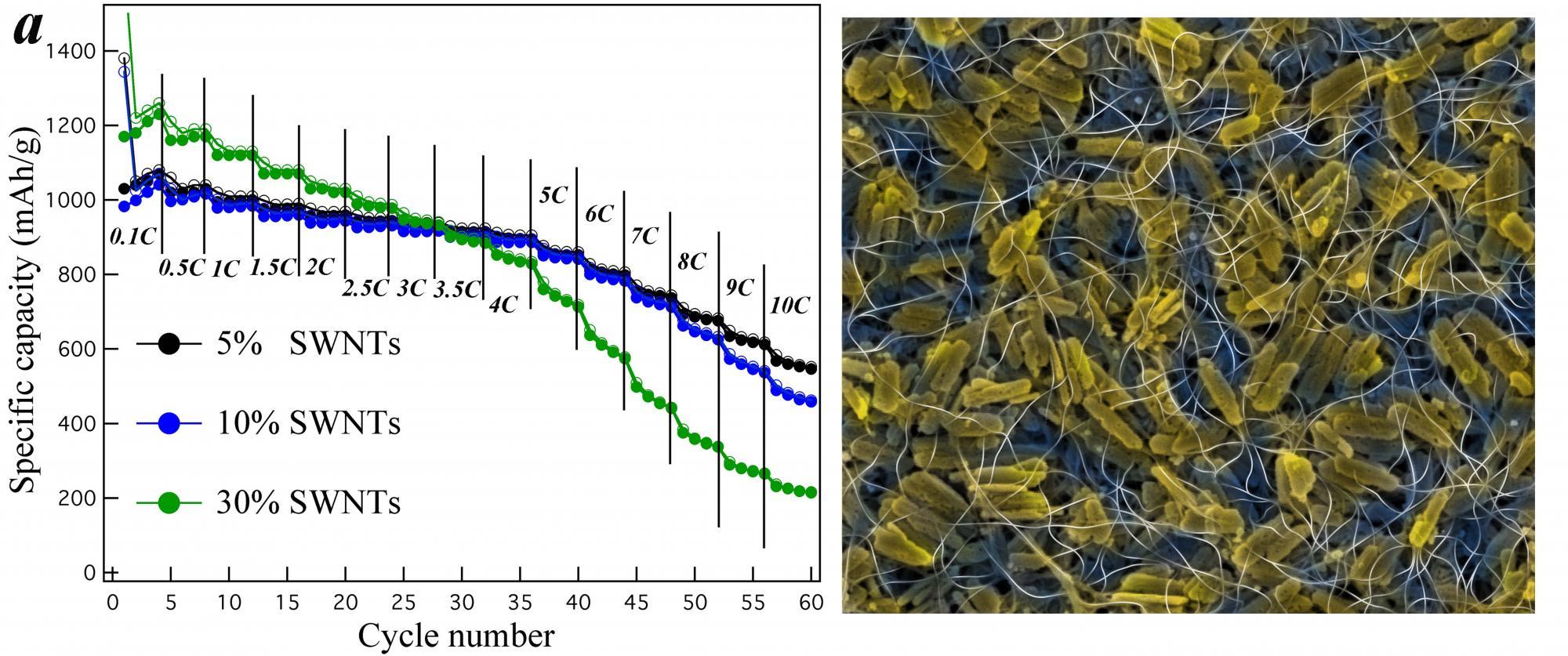

Binder-free high-rate capability Li-ion anodes, utilizing Fe3O4 nanorods and carbon nanotubes.

Adv. Energy Mater. 2010

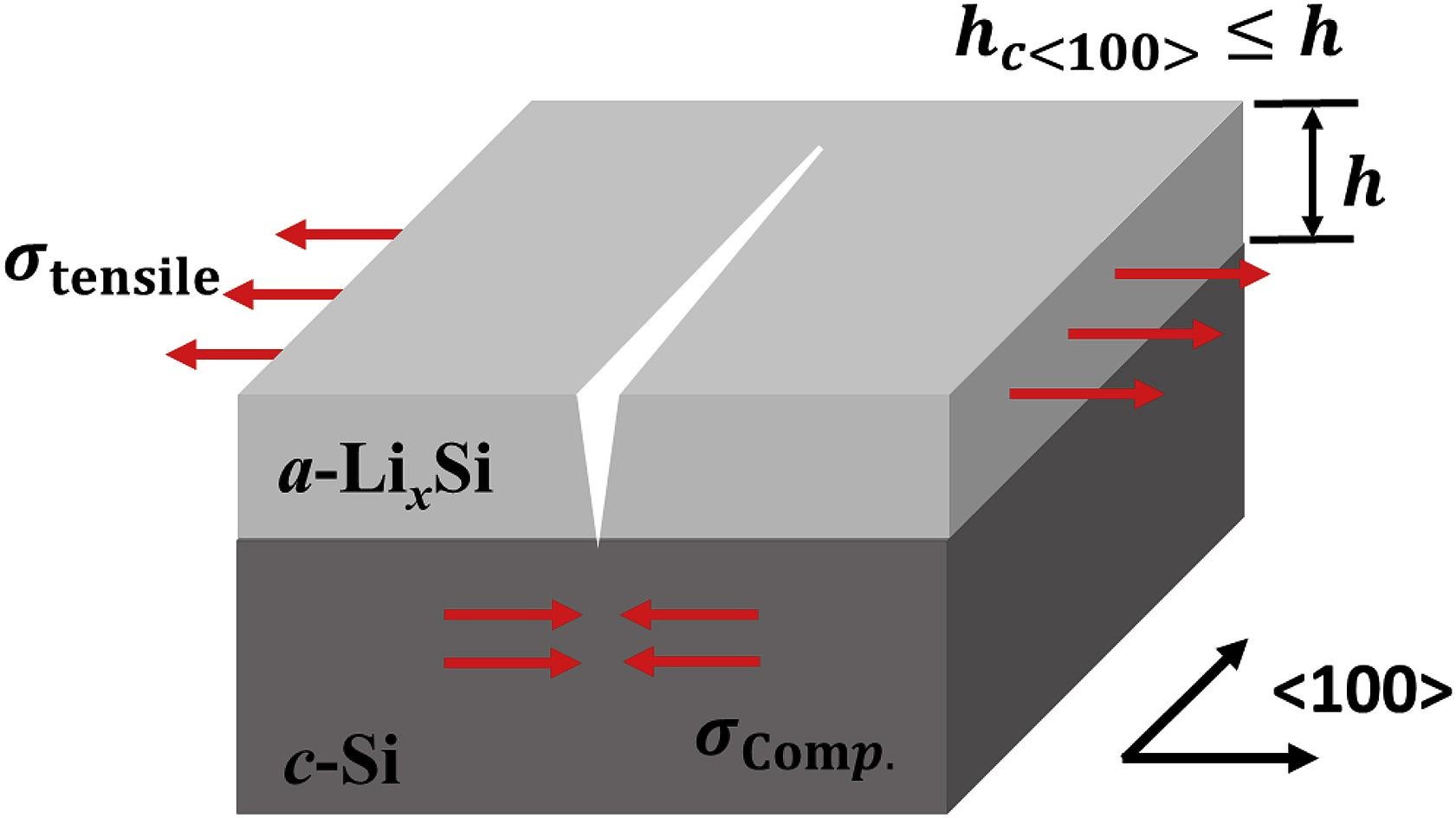

Our recent discovery on electrochemically induced fracture behavior with the focus on the crack nucleation and cracking propagation at early-stage of electrochemical reactions. We introduce linear elastic fracture mechanics—used for multi-layer structure—to investigate underlying mechanism for crack nucleation and propagation.

J. Power Sources, Comm. 2019

The enhanced mechanical properties of the surface modified electrodes, confirmed by mechanical characterization, can help accommodate the repeated volume fluctuations, preserve the electrode microstructure during electrochemical reactions, and thereby, leading to a remarkably improvement of electrochemical performance.

ACS Applied Mater. Inter. 2017

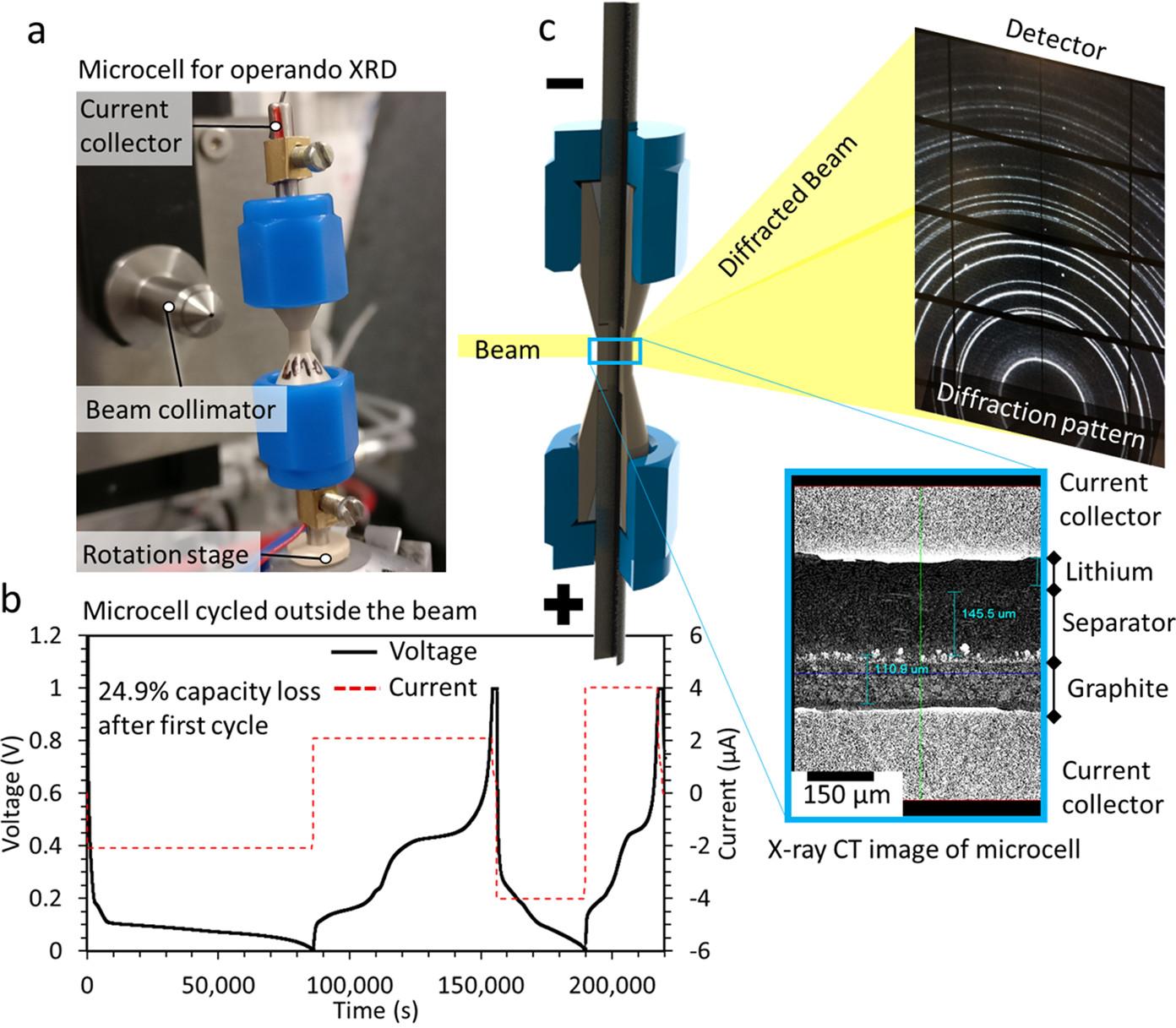

We present the first demonstration of combined high-speed X-ray diffraction (XRD) and XRD computed tomography (XRD-CT) to probe, in 3D, crystallographic heterogeneities within Li-ion electrodes with a spatial resolution of 1μm. The local charge-transfer mechanism within and between individual particles was investigated in a silicon(Si)-graphite composite electrode. High-speed XRD revealed charge balancing kinetics between the graphite and Si during the minutes following the transition from operation to open circuit.

Nano Letter 2019

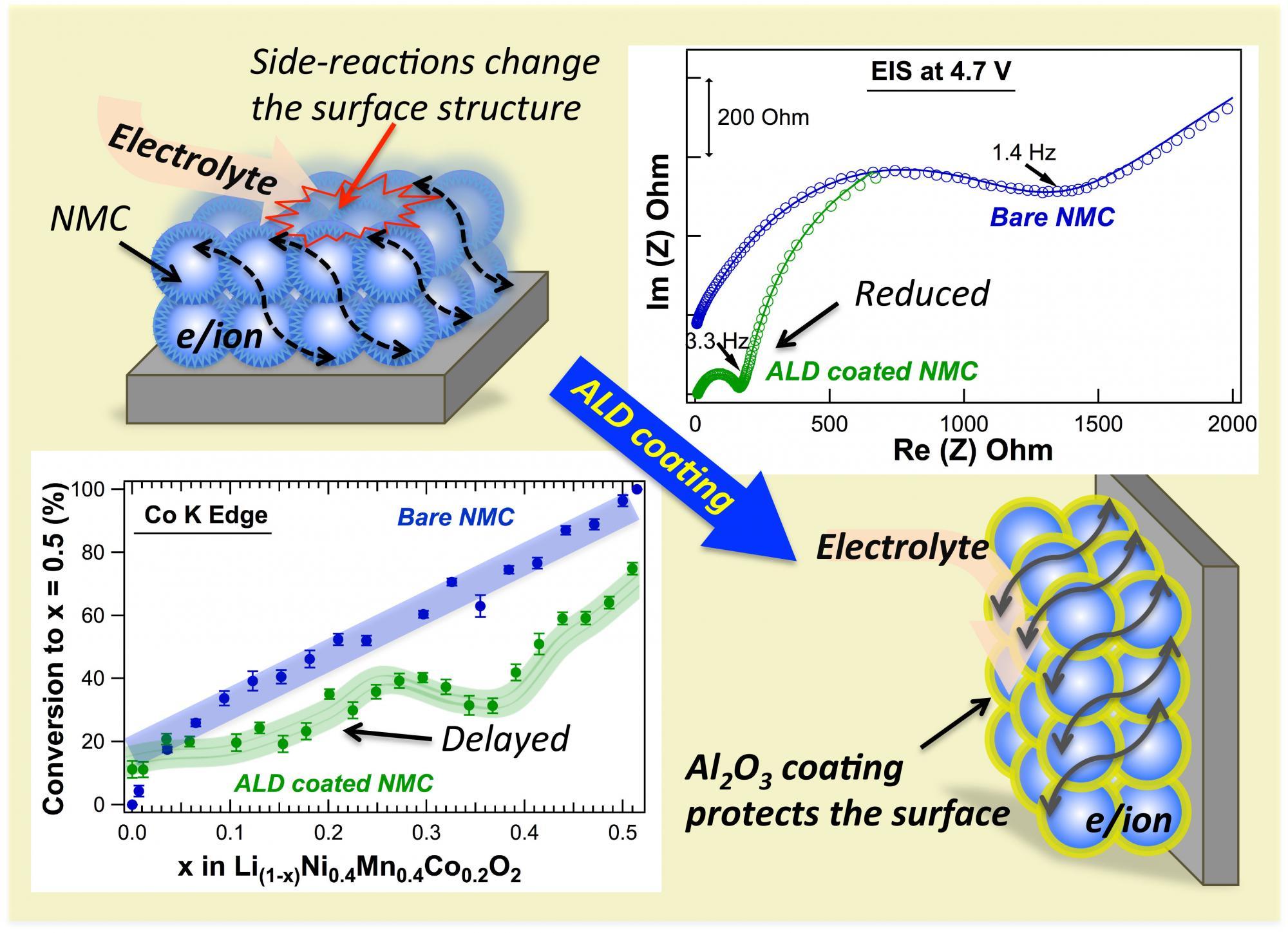

To understand the effect of the Al2O3 coating, electrochemical impedance spectroscopy, operando synchrotron-based X-ray diffraction, and operando X-ray absorption near edge fine structure spectroscopy have been utilized to characterize the structure and chemistry evolution of the LiNi0.4 Mn0.4 Co0.2 O2 cathode during cycling.

Chem. Mater. 2017

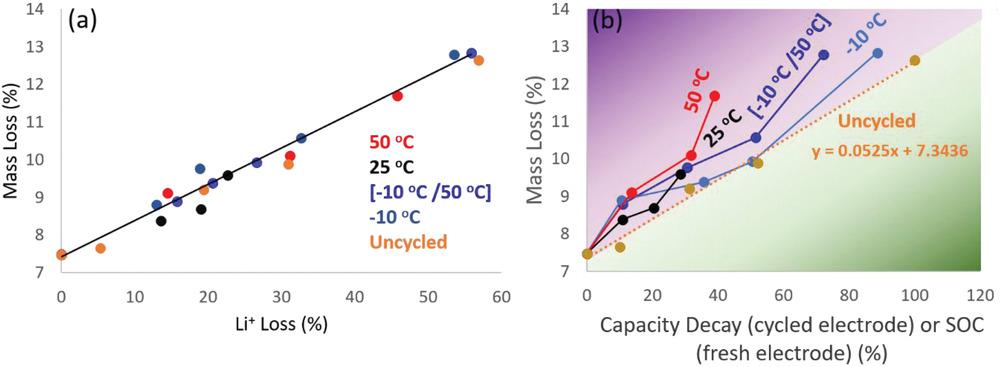

We introduced a new methodology to quickly determine the lithium content in spent cathode materials (LiNixMnyCozO2, x + y + z = 1, NMC) using a thermalgravimetric analysis, which bypasses the use of ICP−MS and significantly reduces the cost and time required for determining the lithium content. Based on this new method, a new approach is developed to identify spent cathode materials suitable for direct relithiation recycling.

Advanced Sustainable Systems, 2020

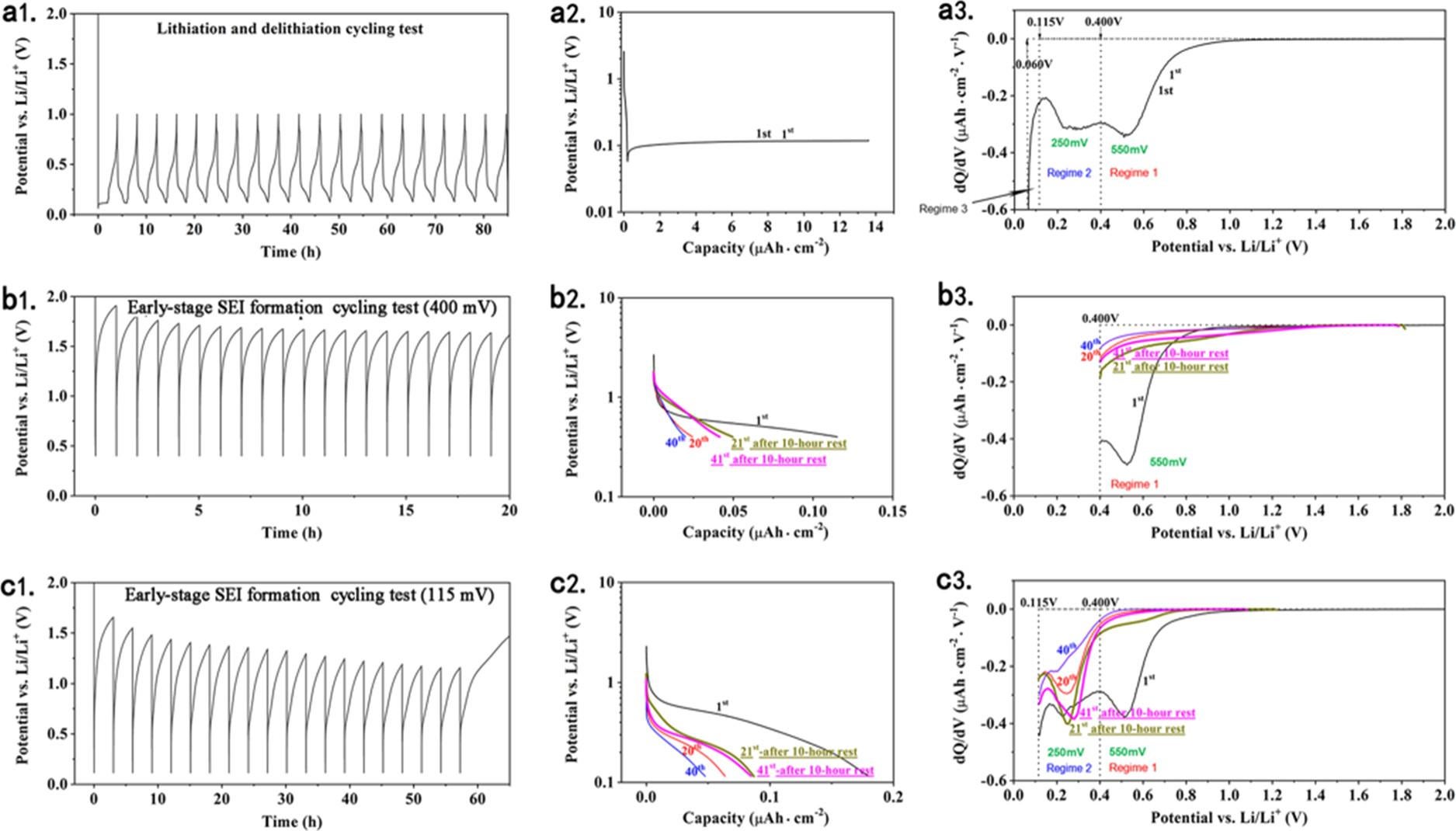

In this work, we found that the chemical formation process of a proto-SEI on Si is closely entangled with incessant SEI decomposition, detachment, and reparation, which lead to continuous lithium consumption. Using a special galvanostatic protocol designed to observe the SEI formation prior to Si lithiation, we were able to deconvolute the electrochemical formation of such dynamic SEI from the morphology and mechanical complexities of Si and showed that a pristine Si anode could not be fully passivated in carbonate-based electrolytes.

ACS Applied Materials & Interfaces, 2020 (https://doi.org/10.1021/acsami.0c03799)

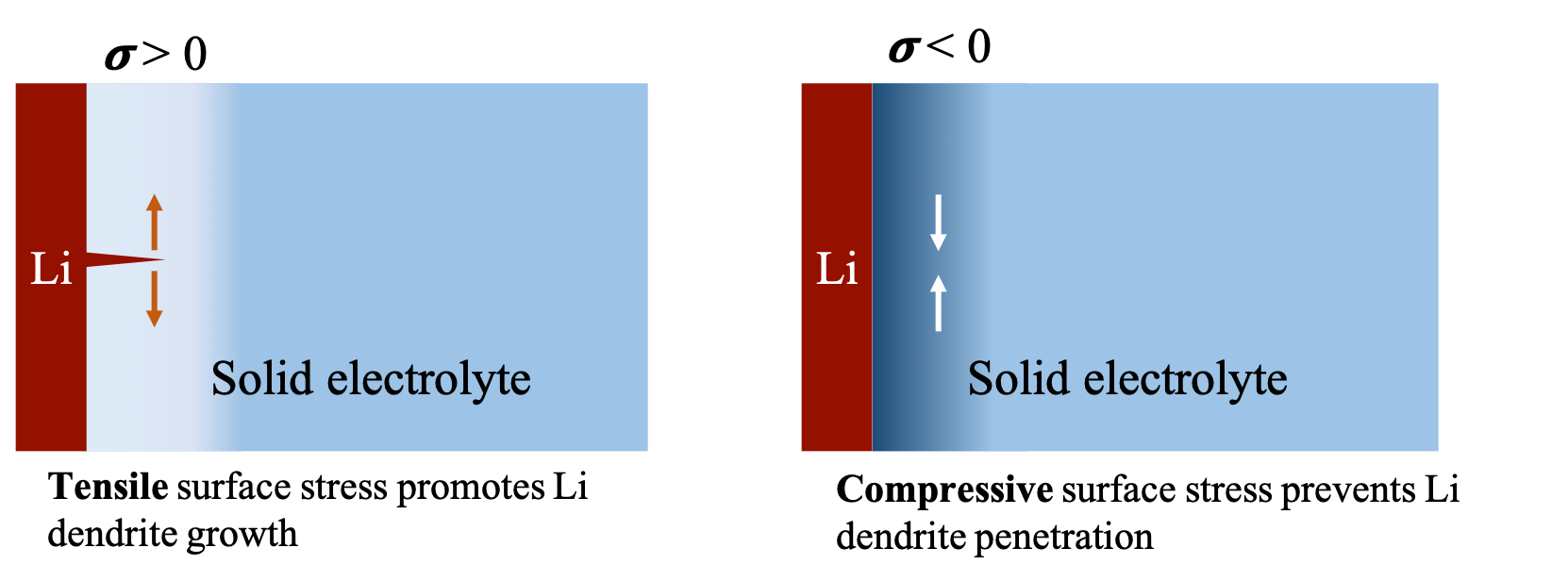

This Perspective proposes a solution to dendrite penetration that is completely new to the battery field, one that we believe will unlock new research areas for improved SEs.

November 2020 Joule 4(12)

DOI:10.1016/j.joule.2020.10.009