Dynamic Windows

Dynamic windows with adjustable tint allow electronic control of the flow of light and heat and offer enormous potential for reducing energy use in buildings. According to the DOE, up to 5% of annual U.S. energy use (the equivalent of 300 million metric tons of CO2 emissions) will be saved if buildings upgrade to dynamic, highly-insulating windows.1 These windows could also help mitigate and adapt to climate change by making the electrical grid more resilient by preventing overheating of buildings through west-facing windows late in the day when the amount of electricity available from solar cells for air conditioning is winding down. Dynamic windows also address problems with glare and comfort that plague conventional windows and help occupants maximize natural daylight that improves their mood, health and productivity.2

The current state-of-the-art dynamic glass made by View, Sage and Kinestral uses electrochromic oxides that require complex processing and materials and are too expensive for widespread market adoption (> $50/sq. ft.). The electrochromic oxides are absorptive (instead of reflective like metals) and only allow the visible light transmission (VLT) to change from 64% to 2% (or 50% to 0.1% if two dynamic glazings are stacked), which reduces potential energy savings.3 The limited optical contrast also omits application in the residential market where privacy is a requirement. The materials preferentially transmit blue light, which makes the color of the windows unacceptable for many applications. Despite 40+ years of R&D and over $2 billion of investment, the incumbent dynamic window technology has only achieved minimal market penetration due to the aforementioned challenges of cost, color and contrast.4

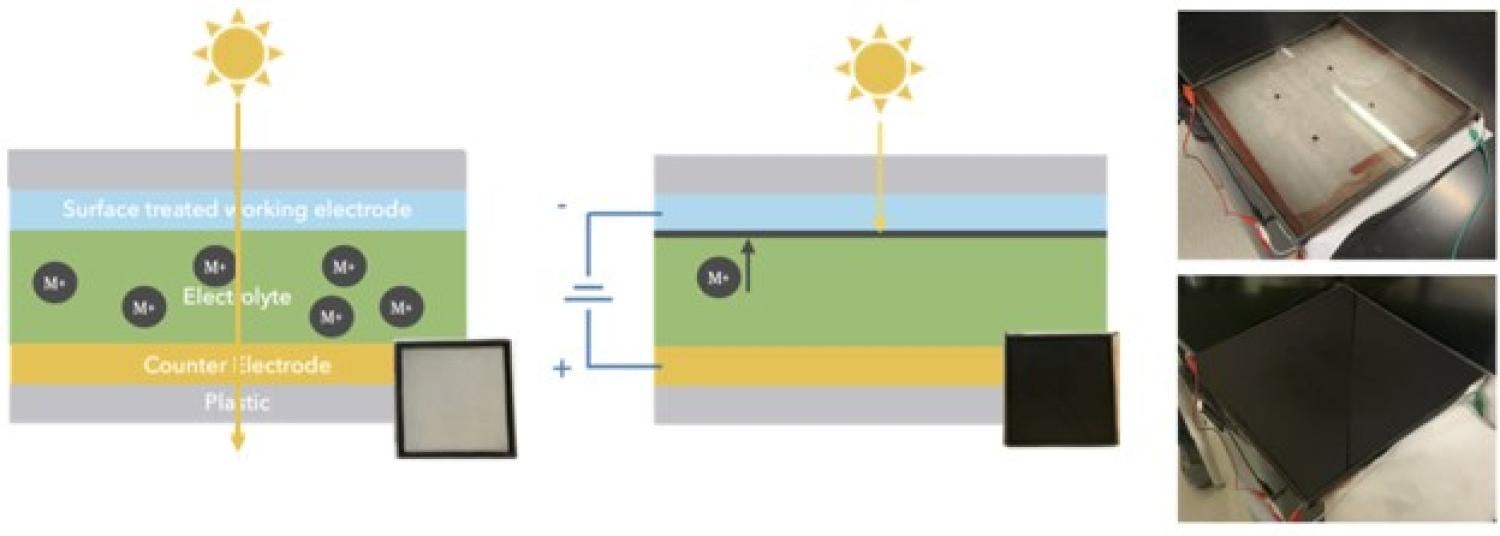

Reversible metal electrodeposition (RME) is a promising approach for dynamic windows that addresses the problems of traditional electrochromic windows related to cost, color and contrast. In these windows, metal is plated on a transparent electrode when a reductive potential is applied (-0.7 V). The metal can be stripped to make the window clear again by applying an oxidative potential (+0.7 V). To date, we have developed RME dynamic windows with competetitve switching speeds, neutral color (|a*,b*|<5 at all tint states), respectable durability for early-stage research, improved thermal control, <2% haze, and a distnict 'privacy state' for residential applications. We have also demonstrated dynamic windows that switch uniformly over a 1 sq. ft. scale and boast the widest dynamic range of any existing technology.

Projects for the windows team are focused on improving the durability of our dynamic windows to pass the ASTM 2141-14 standard (50,000 cycles at 85C and 1 sun with UV-illumiation over 5,000 hours).

This technology is being commercialized by Tynt Technologies.

1. Building Technologies Office. R&D Roadmap for Emerging Window and Building Envelope Technologies. United States Dep. Energy 26–30 (2014).

2. View Dynamic Glass. Daylight and The Workplace Study. (2018).

3. Kinestral Technologies Inc. Halio ® Insulated Glass Unit (IGU). Available at: https://www.kinestral.com/resources/halio-insulated-glass-unit-igu/.

4. Dynamic Glass | Project Drawdown. Available at: https://www.drawdown.org/solutions/dynamic-glass.