The U.S. Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) has awarded CU-Boulder a three-year, $3 million grant to develop cooling technology that will enable efficient, low-cost supplementary cooling for thermoelectric power generation.

The U.S. Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) has awarded CU-Boulder a three-year, $3 million grant to develop cooling technology that will enable efficient, low-cost supplementary cooling for thermoelectric power generation.

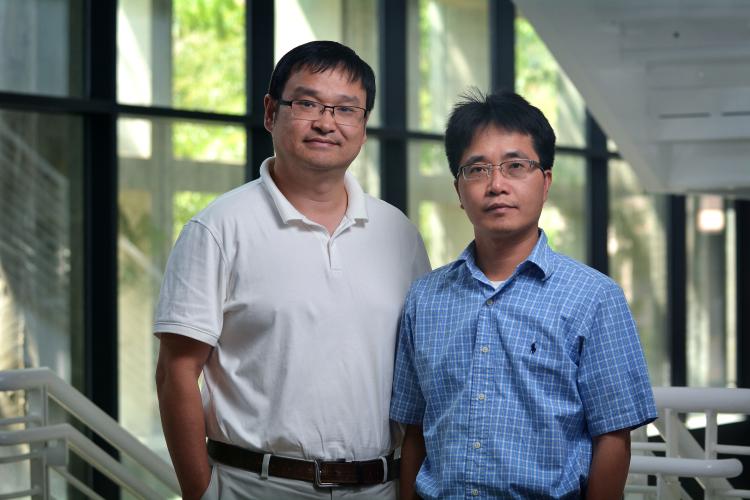

CU-Boulder’s research team, led by Ronggui Yang, associate professor of mechanical engineering, will develop cold storage modules and a system called RadiCold, which cools by infrared thermal emission. If successful, the design could provide power plant operators a low-cost way to supplement cooling without using as much water as they do now.

“I am confident that we will be successful in developing this novel cooling technology that could be useful for both power plants and buildings,” says Yang.

In thermoelectric power generation, only 40 percent of the energy in the fuel is used for power generation. The remaining 60 percent becomes low-grade heat that needs to be carried away by cooling systems.

There are two types of cooling systems: Wet cooling systems use water resources such as a river, lake or ocean and pass it directly over tubes containing condenser water, and then return it, warmer, to the original source. Dry cooling systems use air to cool condenser water.

Most U.S. power plants use wet cooling technologies because water can cool better than air, which allows power plants to operate more efficiently. In fact, thermoelectric power plants are among the biggest consumers of fresh water in the world. About 139 billion gallons per day—or 41 percent of total fresh water withdrawal—is used to cool condenser water. Three percent of the cooling water is evaporated and lost. This has an enormous environmental impact, especially in areas already suffering from fresh water shortages. These systems also release heat waste into the environment, which adversely affects wildlife, says Marta Zgagacz of CU’s Office of Technology Transfer. Zgagacz is on the team that will evaluate the commercialization potential of this innovative technology.

Researchers say dry cooling has the potential to significantly reduce water consumption, but the high cost and low efficiency of current technologies discourage their use.

Improved air-cooled heat exchangers can help overcome these challenges. Since air-cooled heat exchangers can only cool water temperatures as low as the surrounding temperature, supplemental cooling technologies—such as RadiCold—are needed to further decrease water temperatures in certain conditions.

Methods to cool a building roof by sending long-wavelength infrared light into the dark night sky have been known for a long time. However, cooling under direct sunshine and, more critically, manufacturing these cooling systems in a scalable and cost-effective way are areas ripe for research, says co-principal investigator Xiaobo Yin, an assistant professor in both mechanical engineering and in the materials science and engineering program.

A RadiCold surface reflects sunlight and allows cooling for both daytime and nighttime power plant operation.

“I am excited to work with my colleagues at CU-Boulder to transform innovative materials and component research into engineering systems,” says Gang Tan, assistant professor in the Department of Civil and Architectural Engineering at the University of Wyoming and a co-principal investigator. “I also foresee great potential in building energy savings by developing cooling roof and ceiling systems using RadiCold surfaces.”

In addition to these senior researchers, the team will include three postdoctoral research associates, three doctoral students and a few undergraduate students. Two MBA students from the CU-Boulder Leeds School of Business will work closely with the team on technology to market analysis.

Tony Tong, associate professor of strategy and entrepreneurship at the Leeds School, is also part of the team that will commercialization potential of this innovative technology.