Classes Are Open, Register Today

Beginning Welding

The feedback has been incredible on this. The class begins with the first day being dedicated to satety and welding fundamentals, wrapping up with 30 minutes of getting geared up and cutting plates, shapes and pieces out of steel sheet with our plasma cutter. Everyone just wants to keep going!

That enthusiasm is carried through the rest of the week, with the fundamentals of TIG and MIG welding being learned and practiced intensely. Everyone leaves at the end with one or more things they have made, with a chosen emphasis on their preferred discipline.

We absolutely insist on teaching everyone the skills involved in welding aluminum, a skill that is one of the most useful in todays world.

Class Outline

Class Outline

- Proper gear for safe welding.

- Learn the use/care/storage of gas cylinders.

- Choosing the right metal for success.

- How to identify different types of metal.

- The fundamentals and practice of MIG and TIG welding.

Class Details

Location: C1B29 Duane Physics Building (main level, west hall)

Location: C1B29 Duane Physics Building (main level, west hall)- Cost: $300 payable via cash/check/IN on the first day of class.

- Classes are small - usually 4 students per class.

- All materials and safety gear are provided.

- Full attendance the week of class mandatory.

Students must be at least 18 years or older to take the class; age verification may be required.

Machine Shop and Technology Safety

Class Description

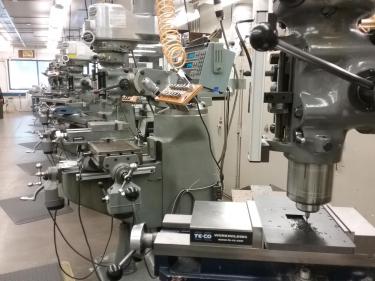

Everyone who takes this class is excited that they actually get to make things! The goal is to have all participants leave at the end of the week with one item they have made on a lathe and another on a vertical mill. It is very hands-on and intense, learning and putting into practice the skills of precision measurement, precise drilling, threading holes, machining parts to precise tolerances, milling slots and finally, assembly of their projects.

Everyone who takes this class is excited that they actually get to make things! The goal is to have all participants leave at the end of the week with one item they have made on a lathe and another on a vertical mill. It is very hands-on and intense, learning and putting into practice the skills of precision measurement, precise drilling, threading holes, machining parts to precise tolerances, milling slots and finally, assembly of their projects.

Class Outline

- Safety, proper dress and PPE.

- Fundamentals of essential skills, their history and relevance.

- Familiarity using most common equipment and understanding tooling in a machine shop.

- Cutting and prepping materials needed for projects.

- Reading and understanding dimensions on engineering drawings.

Class Details

- Location: C1B29 Duane Physics Building (main level, west hall)

- Cost: $300 payable via cash/check/IN on the first day of class.

- Classes are small - usually 4 students per class.

- All materials and safety gear are provided.

- Full attendance the week of class mandatory.

Students must be at least 18 years or older to take the class; age verification may be required.